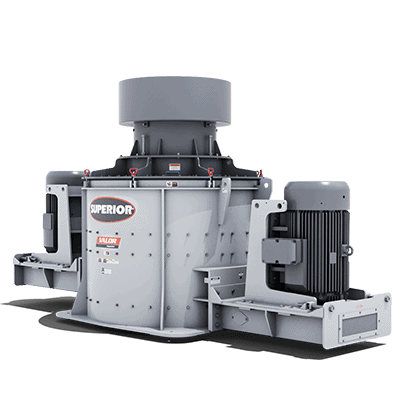

Valor® Vertical Shaft Impactor (VSI)

Produce Uniform, Road-Building Material

Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at higher tonnages and allow for more customization of rock shape and size.

Our Valor VSI offers significant application flexibility because of options like adjustable chamber configurations and several unique rotor options. Investments are backed by an industry-leading 2-year or 6,000-hour warranty.

Applications:

Manufactured Sand

Material Benefication

Precious Metals Recovery

Re-Crushing Inventory

Fractured Gravel

Cubicle Products

Man-Made Materials

Cement Clinker

Concrete Rock

Chips

Shaping

Asphalt

Advantages

01.

Hydraulic lid

Along with additional defenses, a hydraulically-controlled lifter allows safe access to chamber.

02.

Feed Tube Adjustment

Allows operators to externally adjust the feed tube for production control without opening the crusher.

03.

Air Transfer System

Available on all models, the design reduces harmful dust emissions during operation.

04.

Vantage® Automation

Designed and supported in-house, automation allows precise control, warns of harmful conditions, and improves efficiencies.

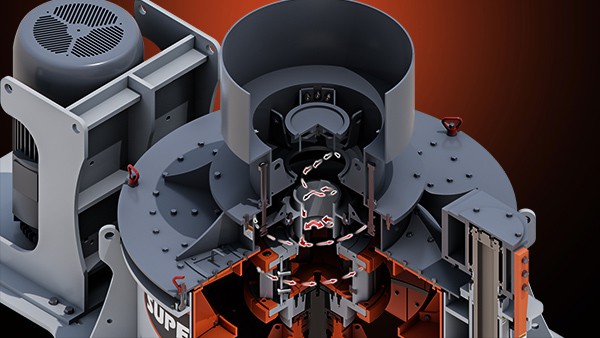

How Does A VSI Work?

During operation, feed material contacts the VSI’s rotor which rapidly launches it against stationary anvils. This collision causes the rock to break along its natural fault lines.

VSI’s are typically positioned after primary or secondary crushers and consistently produce cube-shaped material, including Superpave, which is often required by most modern contractors.

Local Stock. Local Support. Local Experts!

Impact Crushers

benefits of impact crushing

When utilized correctly, impact crushers are absolute rockstars! They produce some of the highest value, highest quality material in the aggregates industry.

Video

Animated overview of VSI crusher features.

Back to top »

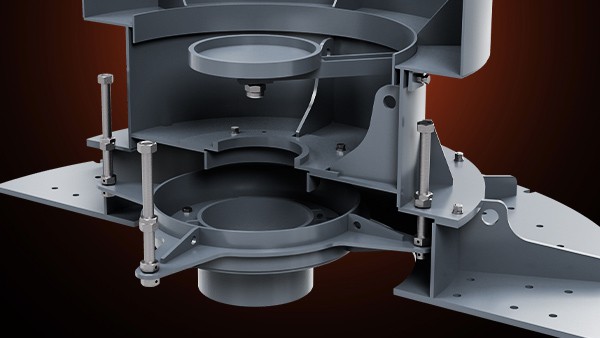

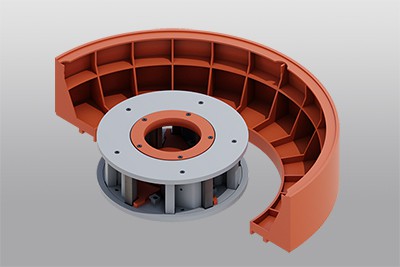

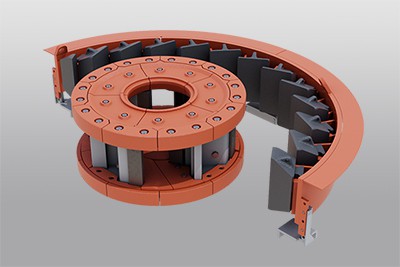

VSI Chamber Configurations

ROCK ON ROCK

Enclosed rotor and rock shelf

High abrasion applications (i.e. Quartz)

Interchange top and bottom rotor parts

ROCK ON STEEL

Fabricated rotor and anvil ring

Medium abrasion materials (i.e. Granite)

Designed with fewest parts possible

STEEL ON STEEL

Open shoes and anvil ring

Low abrasion materials (i.e. Limestone)

4, 5 and 6 shoes available

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Valor Vertical Shaft Impactor (VSI)

See our privacy policy.