Screening Equipment

Size It

Screening and vibratory equipment take in various shapes, separate the material into consistent sizes and dispense a uniform product from as many as five unique discharge points.

It’s why we like to compare Superior screening equipment to the highest paying slot machines in Las Vegas. After understanding your application, we’ll build you a screen that consistently pays.

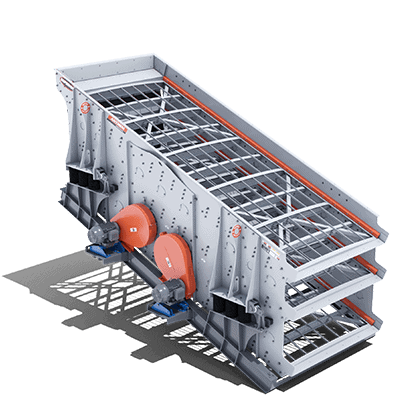

Anthem® Inclined Screen

Operates at sharp angle

(15° – 20°)

Offers highest processing rate

Best suited for stationary plants

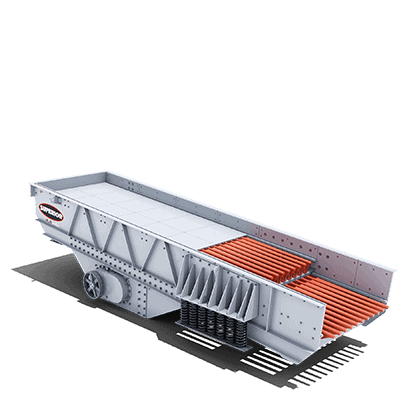

Guardian® Horizontal Screen

Operates at flat angle

(0° – 10°)

Offers best sorting efficiency

Great for portable applications

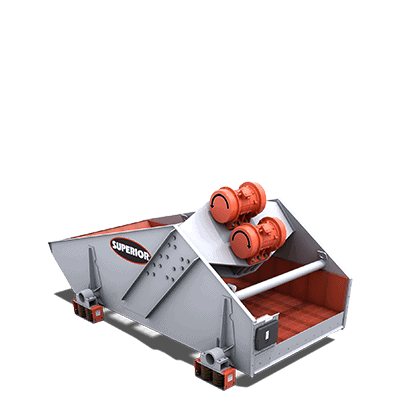

Intrepid® Vibrating Grizzly Feeder (VGF)

Feeds material to crushing or processing plant

Separates and removes undersized materials

Provides continuous feed to crusher

Dewatering Screen

Removes water from material

Enhances (or replaces) sand screws

Produces dryer, cleaner aggregate