Sentry® Horizontal Shaft Impactor (HSI)

Sustainable Material Recycling

Horizontal Shaft Impactors (HSI) are widely used in demolition, aggregate recycling, or operations producing road base material.

That’s because they typically handle a wider range of material and produce less fines than VSI crushers– two features important for concrete and asphalt recycling or crushing glass and bricks.

Superior’s Sentry HSI is a rugged and resilient horizontal impact crusher capable of processing large feed sizes from dirtier conditions.

Applications:

Clay & Brick Crushing

Quarried Stone

Recycle Concrete

Cubical Products

Recycled Asphalt

Advantages

01.

Spacious Chamber

Designed with proper spacing inside the chamber for processing larger feed sizes (up to 40”/1,000mm).

02.

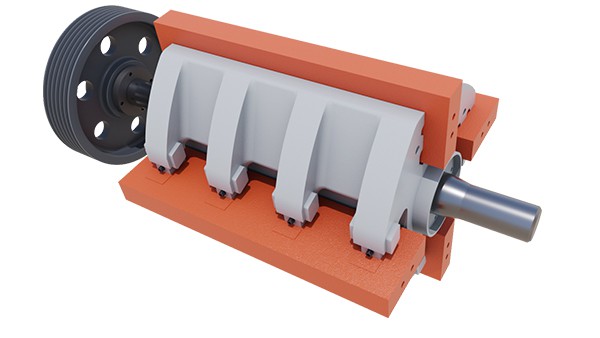

High-Powered Rotor

A cast closed design creates the highest possible inertia producing a maximum crushing force.

03.

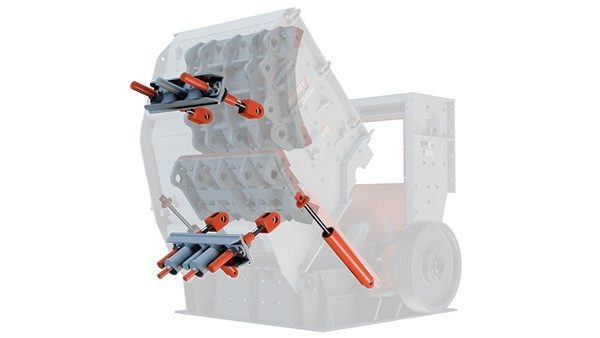

Convenient Hydraulic functions

Hydraulically-designed components include curtain adjustments and opening/closing of the chamber.

04.

Universal Side LIners

Mix and match these commonly-shaped liners to prolong wear life and decrease replacement costs.

How An HSI Works

Upon entry, feed material quickly contacts a series of blow bars spinning rapidly on a rotor.

These blow bars (hammers) violently toss the rocks against steel curtains (aprons) causing the material to break. Eventually, newly shaped rock exits the opening at the bottom of the HSI.

Local Stock. Local Support. Local Experts!

Impact Crushers

benefits of impact crushing

When utilized correctly, impact crushers are absolute rockstars! They produce some of the highest value, highest quality material in the aggregates industry.

Videos

Animated overview of Sentry HSI Crusher features.

New HSI Closed Circuit Plant displayed at CONEXPO-CON/AGG.

Back to top »

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Sentry Horizontal Shaft Impactor (HSI)

See our privacy policy.