Fine Material Washer

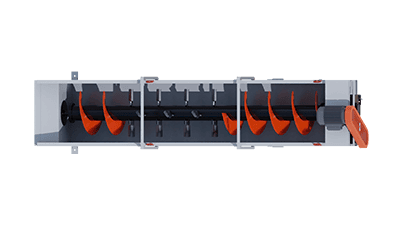

Washing, Classifying & Dewatering Sand Screws

Designed to handle fine materials up to 3/4″ (19mm) in size, these spiral classifiers effectively remove clays, silt, and lightweight contaminants from sand, ensuring a clean and high-quality end product.

As the material progresses up the sand screw’s incline, unwanted particles are washed away, while heavier materials settle to the bottom and are efficiently transported up the tub.

Gravity allows water to drain from the material and the discharged sand is left with a moisture content of about 15-25%

Applications:

Sand

Concrete

Mason & Mortar

Phosphate

Iron Ore

Salt

Advantages

01.

Load Zone Baffle

Calms down the rushing waters to help maximize fines retention and get you more money.

02.

Weir Plate

Adjustable design encourages overflow water to level, which maximizes fines retention.

03.

Belly Pan

Adjustable feature allows control of water bed depth for a cleaner, drier product.

04.

Flushback Nozzle

Utilizes an off-the-shelf, shaft-mounted gear reducer that is fully-guarded during manufacturing.

How Does A Fine Material Washer Work?

As the material enters the screw washer, it encounters a water-filled tub. The screw’s rotating shaft continuously moves the sand in an upward direction, which also creates a mixing action to break up clumps, dislodge fines, and agitate material for efficient cleaning.

Next, water is added to facilitate the washing process and remove impurities, such as clays, silt, and lightweight contaminants.

As material inclines up the tube, excess water drains from the material due to gravity and the material becomes progressively drier before discharging.

Comparing Screw-Based Washers

From all angles, wet screws look pretty similar. However, small design features allow each to perform a unique set of functions.

Fine Screw

Primary Function

Wash sand

Bonus Benefit

Dewatering and some surface cleaning

Feed Characteristics

Slurry

Moisture At Discharge

15-25%

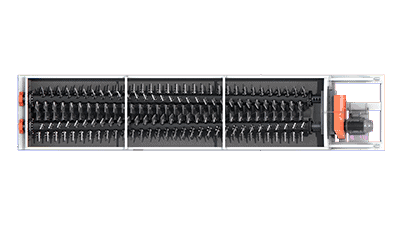

Coarse Screw

Primary Function

Removes sand, slime and dust from gravel

Bonus Benefit

Improves effectiveness of screening

Feed Characteristics

Dry or wet

Moisture At Discharge

10-30%

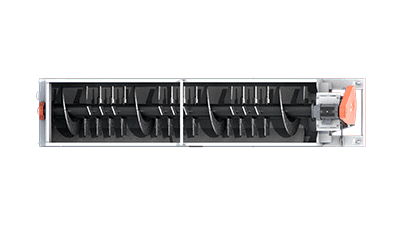

Log Washer

Primary Function

Remove plastic clays from rocks

Bonus Benefit

Reduce deleterious materials

in feed

Feed Characteristics

Usually dry

Moisture At Discharge

10-30%

Blade Mill

Primary Function

Convert dry feed into slurry for screening efficiency

Bonus Benefit

Remove lightweight organic particles

Feed Characteristics

Dry

Moisture At Discharge

40%

Local Stock. Local Support. Local Experts!

models

video

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Fine Material Washer

See our privacy policy.