Impact Cradle

Serve & protect

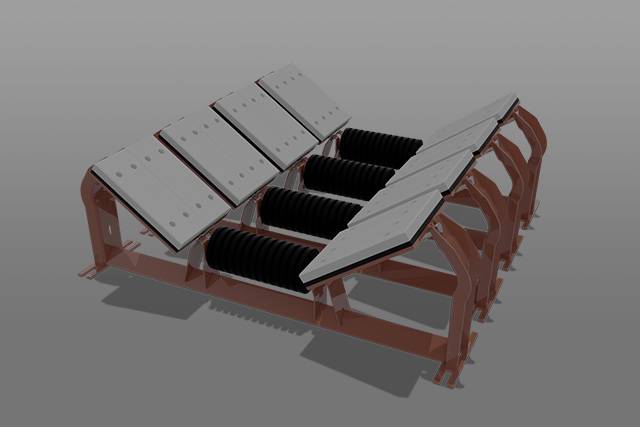

We took impact design a step further and created the impact cradle. Traditionally-designed impact beds do a great job of protecting your conveyor belt from the force of falling material. However, gaps in support leave your belting vulnerable to punctures, rips and tears. That same space – created when the sides of the bed meet the base – can also be a catch point for fugitive material.

Meet the impact cradle. Can you see how its cornerless u-shape matches the contour of your conveyor belt? It eliminates any space between bed and belt.

The picture above shows our Impact Cradle. The frame matches the same footprint as an idler and those black impact cartridges are segmented. Save money and replace cartridge pads individually

because the cartridges simply slide on or off the steel frame.

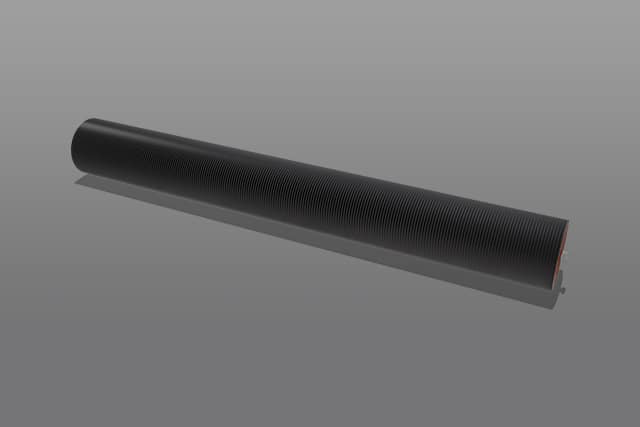

- Belt widths 24” or 72” (609mm – 1,828mm)

- Diameters 5″ – 7″ (127mm – 177mm)

- Troughing angles 20° or 35°

Advantages

01.

Curved Bed

Eliminates harmful space between belt and bed.

02.

impact protection

Urethane segments absorb shock and dissipate contact energy.

03.

urethane segments

Segmented impact bar chunks slide on and off frame for easy replacement.

04.

mounting footprint

Designed to fit into CEMA C, D and E style idler mounting footprints.

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Impact Cradle

See our privacy policy.