Pulleys

CHARACTER DRIVEN

The “driver” is usually the most important component of any moving system and it’s no different with conveyors. Simply put, conveyor pulleys are responsible for driving the belt.

It takes at least two to travel and are categorized as drive or head, return or tail, bend tensioning, snub tensioning or take-up pulleys. Maximum pulley life is essential to cost-efficient material handling and high-capacity production.

Wing Pulleys

Superior was first to introduce the v-shaped wing pulley and quickly after, the Chevron® Pulley became the standard for wing pulleys.

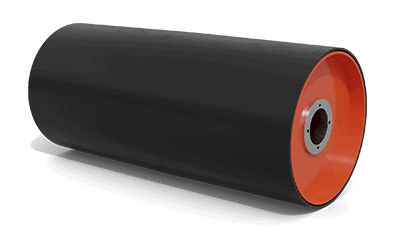

Drum Pulleys

Drum pulleys serve in a variety of roles or positions, including drive, tail, bend tensioning, snub tensioning and/or take-up pulleys.

TAKE-UPS

To prevent belt slippage, portable conveyors are designed with mechanical take-up frames.