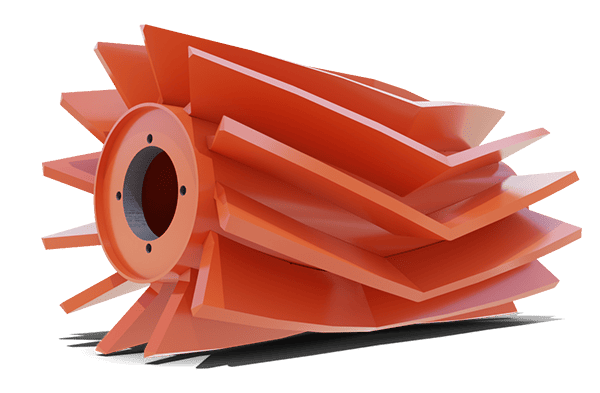

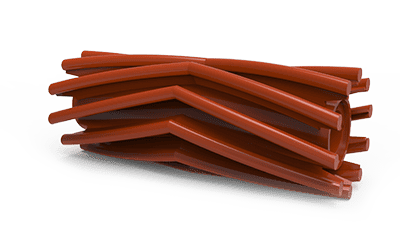

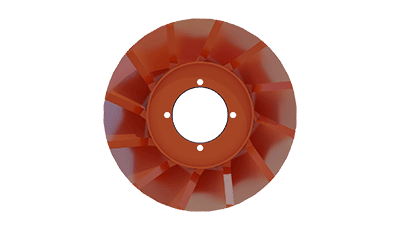

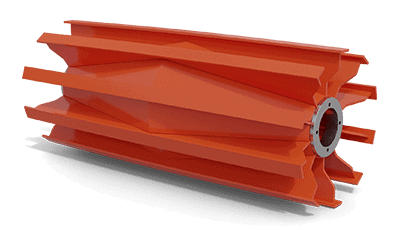

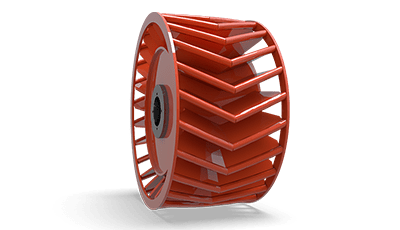

Chevron® Wing Pulley

The Original V-Shaped Wing Pulley

Invented and first introduced by Superior more than two decades ago, the Chevron Wing Pulley has greatly expanded the service life for thousands of rolls of conveyor belting.

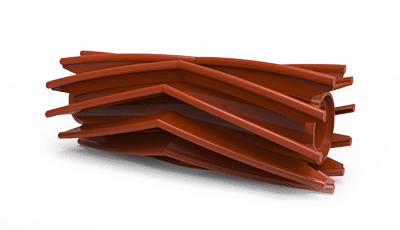

That’s because its unique V-shape sheds fugitive materials more effectively, minimizing the risk of rocks and other unwanted items from getting trapped between the pulley’s wings. Once material is trapped, it can put holes in your belts and cause wings to fold or bend.

Don’t settle for outdated technology. Upgrade to the Chevron Pulley and unlock new levels of reliability and longevity for your conveyor system.

Advantages

01.

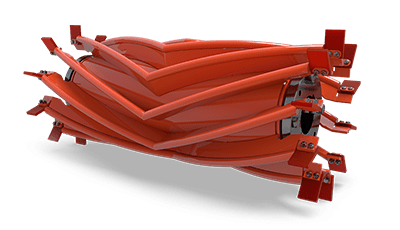

Deflect Fugitive Material

Sheds material out and away from the pulley, preventing it from trapping between wings.

02.

Resists Wing Bending

By design, traditional pulleys have always had wing bending issues. By design, the Chevron Pulley does not.

03.

Longer Lasting Belts

When there’s no fugitive material to puncture belting or bent wings to cause mistracking, conveyor belts last a lot longer!

04.

Less Noise & Vibration

Steady, continuous contact between the pulley and belt reduces noise and vibration by as much as 50 dB per pulley.

Videos

Models

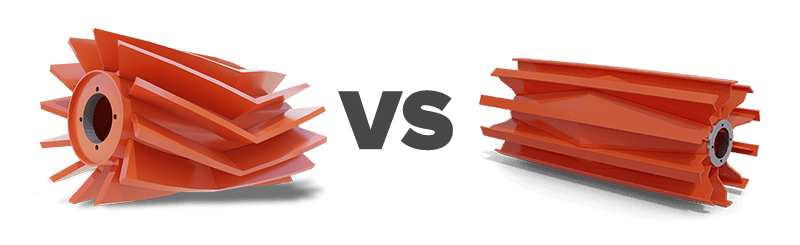

Compare Wing Pulleys

class ranks

CEMA DUTY

APPLICATIONS:

Uniformly-loaded fabric belts with infrequent starts and stops.

DIAMETER:

8” – 36”

1203mm – 914mm

FACE WIDTH:

10” – 78”

254mm – 1,981mm

Mine DUTY

APPLICATIONS:

Fully-loaded fabric belts with frequent starts and stops.

DIAMETER:

12” – 48”

304mm – 1,219mm

FACE WIDTH:

12” – 78”

304mm – 1,981mm

super DUTY

APPLICATIONS:

Fully-loaded fabric belts with frequent starts and stops.

DIAMETER:

12” – 48”

304mm – 1,219mm

FACE WIDTH:

12” – 78”

304mm – 1,981mm

engineered class

APPLICATIONS:

Custom designed pulleys often used with steel cable belts.

DIAMETER:

Custom

FACE WIDTH:

Custom

other wing models

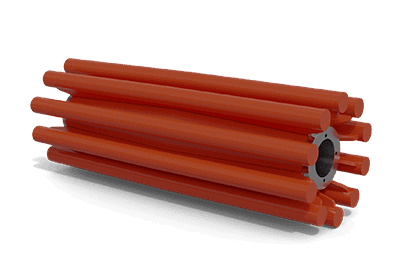

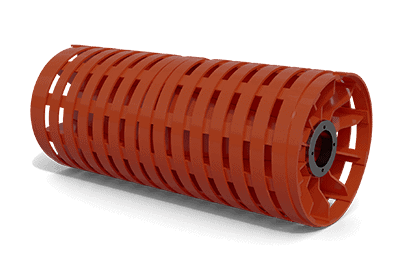

Traditional Wing Flat Bar

Traditional Wing

Round Bar

Spiral Wing

Grain Elevator

Enclosed Belt Chevron Wing

Back to top »

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Wing Pulleys

See our privacy policy.