Classifying Tank

Classifiers Blend to Exacting Specs

Common in dredging or sand applications that require removal — or scalping — of lots of water, Classifying Tanks are capable of accepting a variable out-of-spec feed and will produce a steady in-spec output.

Using a system of high-pressure valves that are computer-controlled, feed material is blended together according to your inputted spec.

Sand classifiers can produce as many as two spec products and one excess product.

Applications:

Manufactured Sand

Sand & Gravel

Fines Retention

Dredging

Water Scalping

Advantages

01.

Elevated Valve Bridge

At least 6” higher than competitors, which prevents water from damaging mechanical parts.

02.

Control System

Computer controls maintain tight specifications, can be controlled from anywhere, and save spec recipes.

03.

Valve Station

High pressure hydraulic hoses encourage faster valve opening and closing, which achieves a more precise spec.

04.

Recirculating Pump

Reduces water usage by recycling tank overflow to the rising current cells.

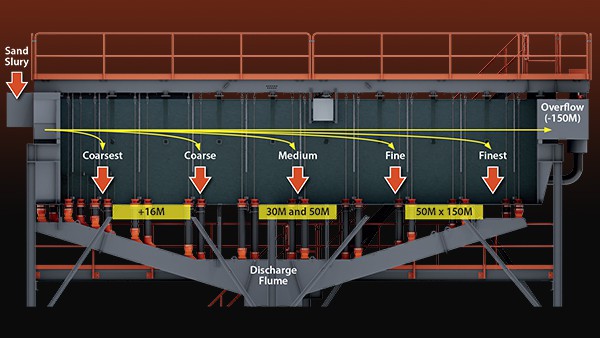

How Does A Classifying Tank Work?

A sand/slurry mix is pumped into the tank through a feedbox. Particles drop in the tank as the velocity of the water slows and allows the material to settle. The coarsest, heaviest sand falls earliest in the process while finer sands settle at the end of the tank.

At the bottom of the tank, valves open and close at different intervals releasing a specific amount of sand from each station. This motion is controlled by the computer according to the blended specs you entered.

Local Stock. Local Support. Local Experts!

Comparing Classifying Technology

When it comes to technology for classifying dry bulk materials, classifiers and sizers are often compared. This table will help you separate broad features of each.

Classifying Tank

Application

Blending of construction aggregates.

Action

Feed is separated and blended into spec products.

Feed equipment

Accepts feed from multiple types of equipment.

feed material

Handles variable feed well.

Water usage

High

Yield

Unit overflow can displace valuable fine sands.

footprint

Large

Maintenance

Multiple moving valves and gauges per station.

Density Sizer

Application

Specialty products like frac or filter sands and glass.

Action

Extremely sharp cut splits feed in two.

Feed equipment

Typically only takes its feed from hydrocyclones.

feed material

Works best when feed is consistent.

Water usage

Low

Yield

No overflow products lost to waste pond.

footprint

Compact

Maintenance

Less with only one moving part to maintain.

Videos

Classifying Tanks are included in Lyman-Richey’s compact washing plant.

Cemstone Products appreciates the precision of material from a Classifying Tank.

Saylorcreek Sand Company uses a Classifying Tank for scalping water from dredge feed.

models

Models

Compare Classifying Tanks

Download the product literature to see skid-mounted and portable models.

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Classifying Tank

See our privacy policy.