Rubber Return Rolls

Pound for Pound

In a troughing position, rubber idlers are typically utilized at the tail end of the conveyor, because they absorb any shock caused by falling material. Without rubber-coated rolls in these transition zones, belting will prematurely wear.

In a conveyor belt’s return position, rubber rolls shed sticky material to help prevent belt tracking issues. Secondly, rubber also generates more friction between the roll and the belt to grip the belt more effectively for better belt tracking.

Lastly, rubber will not break down as quickly as steel in corrosive environments.

Rubber Return Styles

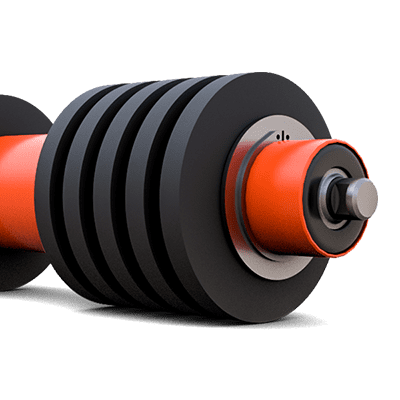

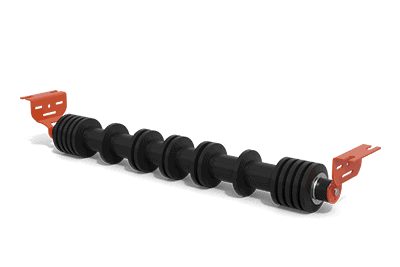

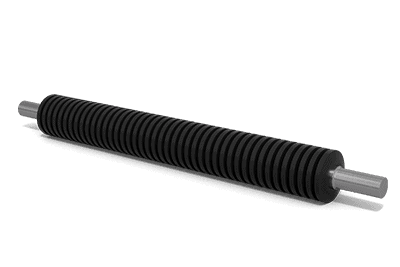

Disc Style

Rubber tires placed throughout roll length; typically used in aggregate applications.

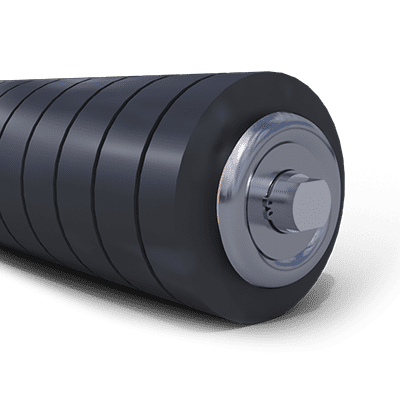

Vulcanized Style

Rubber vulcanized directly to the entire roll; typically used in mining applications.

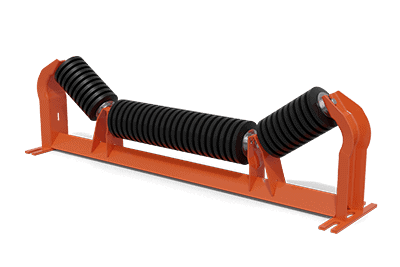

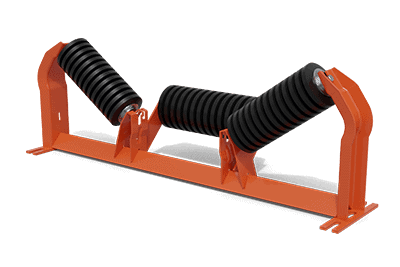

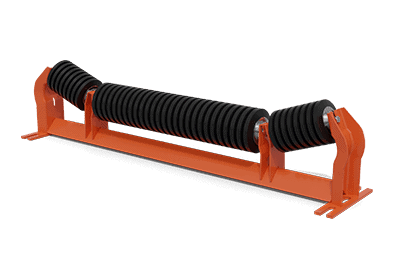

Rubber Idler Styles

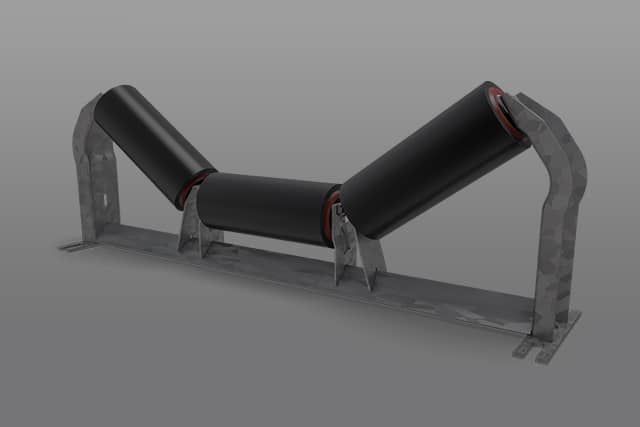

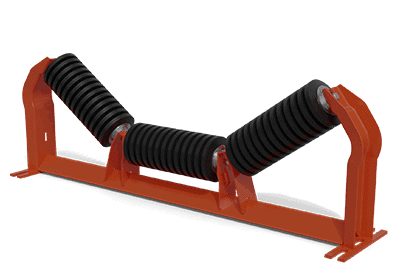

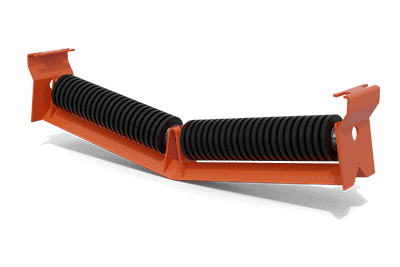

RUBBER TROUGHING idlers

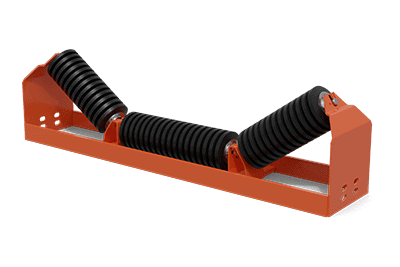

Rubber Equal

Three identical-length rolls for 90% of applications.

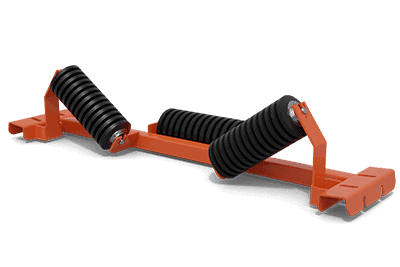

Rubber Unequal

Wide center roll for flat belt applications where material is sorted or picked.

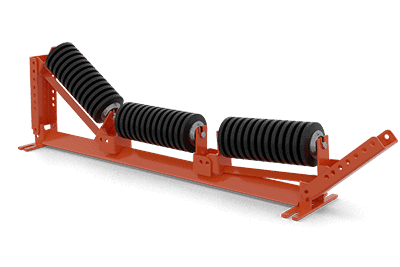

Rubber Offset Center

Often used in grain handling, the center roll position eliminates a pinch point to protect the belt.

Rubber Feeder/Picking

Wide center roll for flat belt applications where material is sorted or picked.

Rubber Flat Carrier

100% flat belt applications where the belt does not form a trough.

Rubber Low Profile

Available in a standard or channel frame mount for applications with height restrictions.

Rubber Wire Rope

Offset center roll with a frame designed for underground wire rope installations.

Rubber Variable Pitch

Adjustable height outside rolls designed to protect belts from sharp transitions.

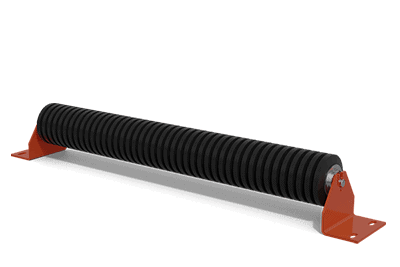

RUBBER RETURN IDLER Styles

Rubber Disc Return Roll

Single roll for applications with no previous

maintenance issues.

Rubber V-Return roll

Manage high capacities while aligning the belt on long distance overland conveyors.

Rubber fixed roll

Fixed to the roll, the shaft rotates with the idler and usually used as carriers on feed conveyors.

Back to top »

The Next Generation Idlers

After decades of field testing and refinement, the next generation of idlers is here.

Superior just completed the biggest idler redesign of your lifetime. Millions have been invested in automated and modern manufacturing.

Reduce maintenance, reduce failure, and protect the belt. Get Superior-built steel idlers made to size for your specific application.

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Rubber idler ROLLS

See our privacy policy.