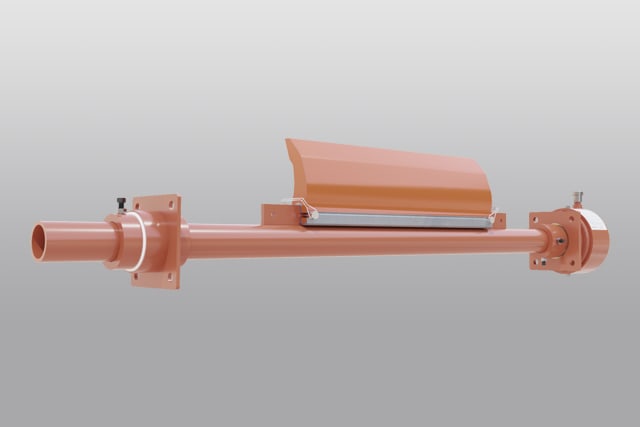

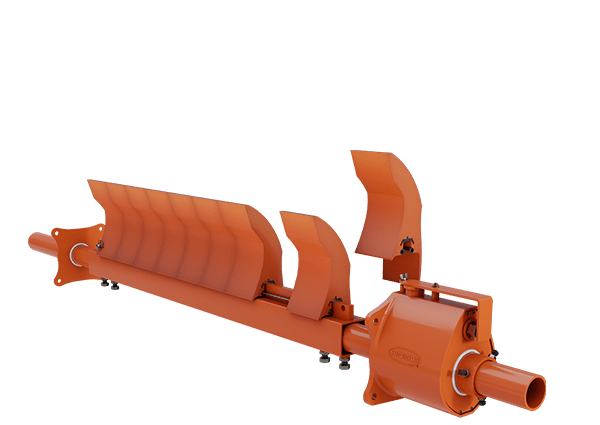

Mine Duty Exterra® Primary Belt Cleaner

Heavy Artillery

Especially in mining applications, where producers handle the most valuable material in the world, primary belt cleaning systems ensure all the wealth is transferred to the money pile.

Primary belt cleaners mount at the head pulley just past the point material is discharged from the conveyor. These urethane-based cleaners scrape the top of the belt and force any stuck on carryback material to the stockpile or other intended target.

- Belt widths 24” – 108” (609 – 2,743mm)

- Blade widths 18” – 102” (457 – 3,590mm)

- Pole lengths 45″ – 133″ (1,143 – 3,378mm)

Advantages

01.

Automatic tension

Patented SFL Tensioner maintains proper pressure against the belt automatically for life of blade.

02.

Blade Profile

Extra bulky urethane blades include a debris flap to prevent buildup against the pole.

03.

Segmented Blades

6” (152mm) segments independently conform to the belt for effective cleaning.

04.

pole system

3-piece system eases installation of heavy duty poles in chutes and tight spaces.

Downloads

Back to top »

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | mine duty Exterra Primary Belt Cleaner

See our privacy policy.