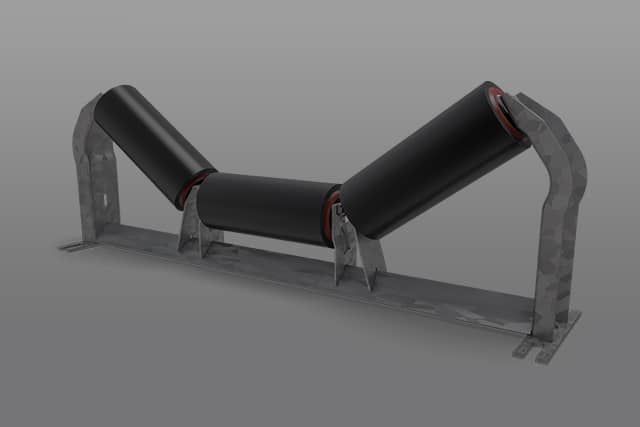

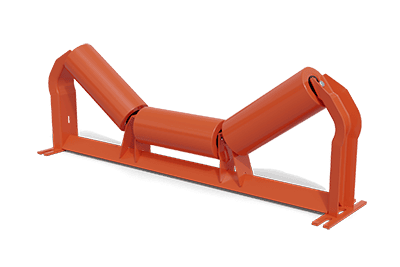

Steel Idlers

Longer Lasting Than Ever Before!

As a vertically-integrated company, Superior is one of the only conveyor manufacturers in the world to use our own components – like idlers, pulleys and scrapers – on our own conveyors. Each year, thousands of idler rolls and frames make the 30-second journey from one end of our manufacturing operation to the other.

This unique integration means we’re intimately connected to the success of our conveyor rolls and idlers. Our product development team consistently seeks feedback, performs tests and reviews conveyor service logs to understand idler performance and generate ideas for new technology.

Advantages

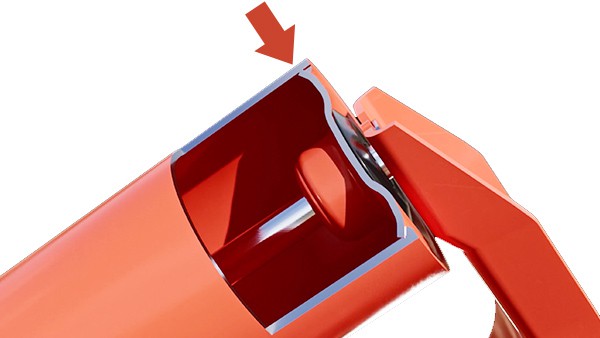

01.

New end disc weld

New ironclad weld at tube to end disc joint for superior quality.

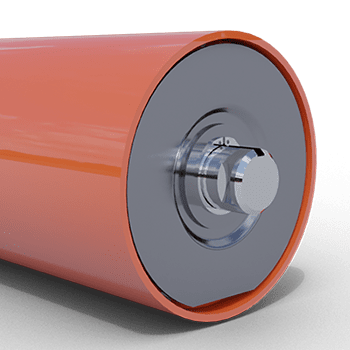

02.

REvamped Idler BEARING Seals

Revamped and enhanced standard idler seal for bullet-proof bearing protection.

03.

Flush, Lipless end disc

One-of-a-kind flush, lipless end disc does not trap material. Watch full animation of the new idler design.

04.

Modern Manufacturing

A $4.5M investment in 2024 added robotic automation for extreme consistency and fast lead times.

The Next Generation Idlers

After decades of field testing and refinement, the next generation of idlers is here.

Superior just completed the biggest idler redesign of your lifetime. Millions have been invested in automated and modern manufacturing.

Reduce maintenance, reduce failure, and protect the belt. Get Superior-built steel idlers made to size for your specific application.

Back to top »

Models – Idler Rolls

STEEL ROLL STYLES

CEMA Rolls

These rolls meet or exceed standards developed and published by the Conveyor Equipment Manufacturer’s Association.

DT Rolls

Double Tube design features inner and outer steel tubes giving the rolls increased rigidity for higher load ratings.

Idler Styles

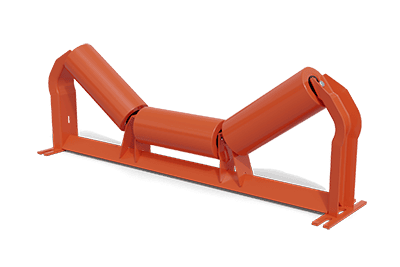

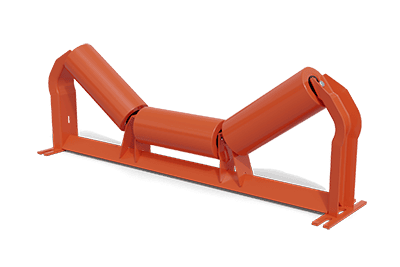

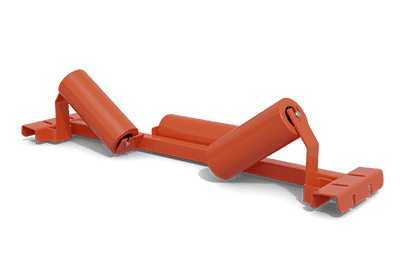

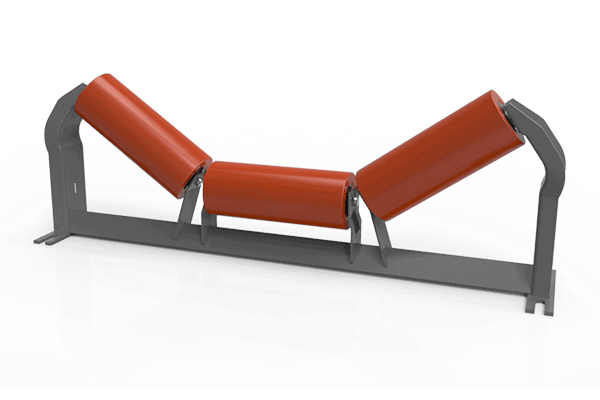

TROUGHING idlers

Equal Troughing

Three identical length rolls for 90% of applications.

UNEqual Troughing

Wide center roll for flat belt applications where material is sorted or picked.

Self-Aligner

Constantly pivots so a mistracking belt is forced to a central position.

Project

Maintain load rating while customizing rolls and frame to meet budget in large projects.

Offset Center

Often used in grain handling, the center roll position eliminates a pinch point to protect the belt.

Feeder (Picking)

Wide center roll for flat belt applications where material is sorted or picked.

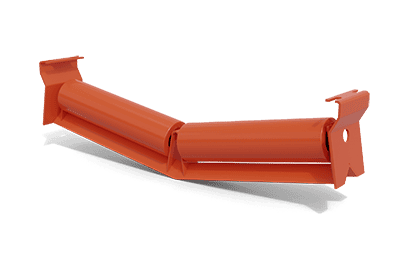

Flat Carrier

100% flat belt applications where the belt does not form a trough.

Low Profile

Available in a standard or channel frame mount for applications with height restrictions.

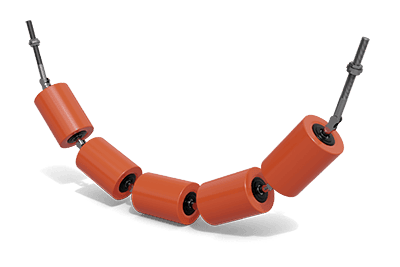

Wire Rope

Offset center roll with a frame designed for wire rope installations typically in overland applications.

Variable Pitch

Adjustable height outside rolls designed to protect belts from sharp transitions.

Retrofit Rolls

Superior manufactured rolls specially-designed for competitor brand frames.

custom

If you constantly fight disruption and maintenance using standard designs, we encourage you to contact us for custom rolls and idlers.

RETURN IDLER Styles

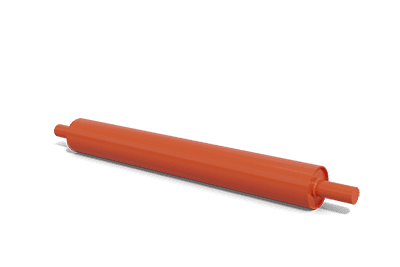

Standard

Return Roll

Single steel roll for applications with no previous maintenance issues.

Self-Aligner

Return Idler

Constantly pivots so a mistracking belt is forced to a central position.

V-Return

Return Idler

Manage high capacities while aligning the belt on long distance overland conveyors.

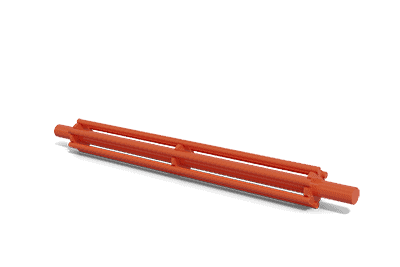

beater bar

Return Roll

Steel rods create a beating motion to free the belt of carryback material.

Live Shaft

Return Roll

Fixed to the roll, shaft rotates with the idler and are usually used as carriers on a feeder conveyor.

Back to top »

INTRODUCING

Project Idlers

Don’t blow your budget on overdesigned idlers. Knowing the load rating, we’ll custom-select the frame and rolls in an economical approach to idler selection.

Idler Classes

From light to heavy to extreme, we build conveyor idlers for a broad set of material handling applications.

Configurations

CEMA B

BEARING

17mm

ROLL DIAMETER:

Up to 5” (127mm)

SHELL THICKNESS:

Up to 5/32” (3.9mm)

CEMA C

BEARING

20mm

ROLL DIAMETER:

Up to 6” (152mm)

SHELL THICKNESS:

Up to 3/16” (4.7mm)

CEMA D

BEARING

25mm

ROLL DIAMETER:

Up to 6” (152mm)

SHELL THICKNESS:

Up to 3/16” (4.7mm)

SUPERIOR DX

BEARING

30mm

ROLL DIAMETER:

Up to 6” (152mm)

SHELL THICKNESS:

¼” (6.3mm)

CEMA E

BEARING

40mm

ROLL DIAMETER:

Up to 7” (177mm)

SHELL THICKNESS:

¼” (6.3mm)

SUPERIOR 40DT

BEARING

40mm

ROLL DIAMETER:

Up to 7” (177mm)

SHELL THICKNESS:

¼” x 2 (6.3mm)

SUPERIOR 45DT

BEARING

45mm

ROLL DIAMETER:

Up to 7.5” (190mm)

SHELL THICKNESS:

¼” x 2 (6.3mm)

CEMA F

BEARING

50mm

ROLL DIAMETER:

Up to 8” (203mm)

SHELL THICKNESS:

¾” (19mm)

SUPERIOR 50DT

BEARING

50mm

ROLL DIAMETER:

Up to 8” (203mm)

SHELL THICKNESS:

¼” x 2 (6.3mm)

SUPERiOR 60DT

BEARING

60mm

ROLL DIAMETER:

Up to 8” (203mm)

SHELL THICKNESS:

¼” x 2 (6.3mm)

–

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | steel idler ROLLS

See our privacy policy.