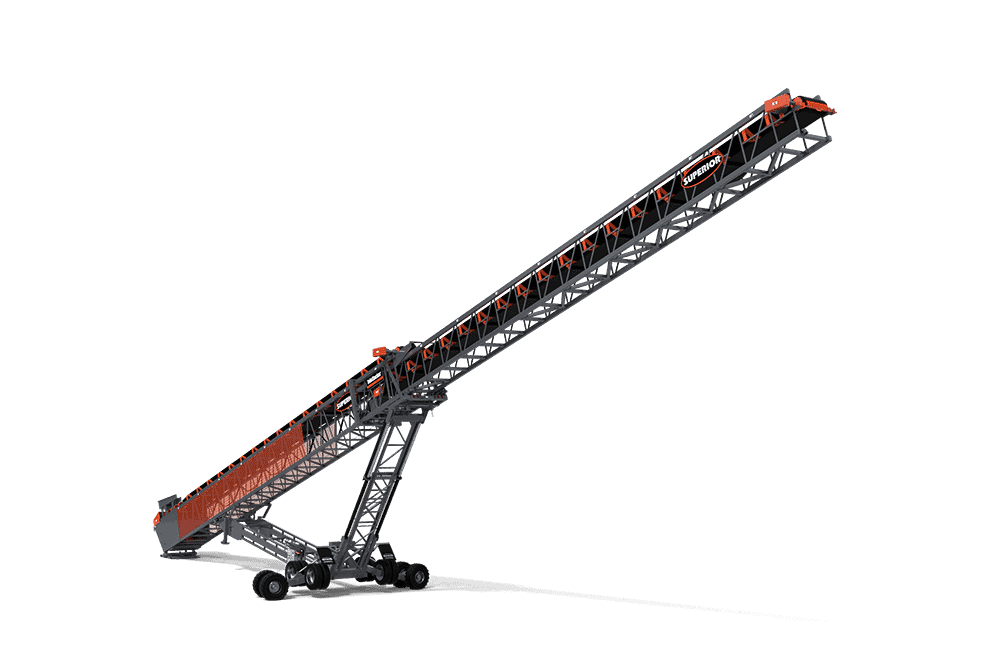

TeleStacker® Conveyor

Unrivaled Performance in Dry Bulk Stockpiling

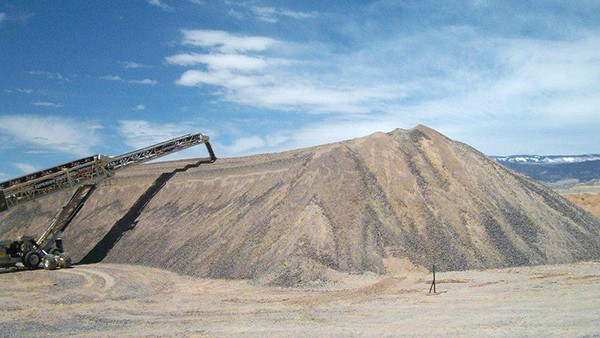

Long known as the “King of the Stockpile,” Superior’s world famous radial telescopic conveyor is a material handler’s most effective weapon against costly stockpile segregation. Its variable height, length, and axle positions allow for layered stockpile construction, which is key to achieving partially and fully desegregated piles.

Today – almost 30 years after its original invention – the TeleStacker Conveyor has earned the reputation as the best-selling portable telescoping stacker in the world and its design has been carefully fine-tuned for hard work and dependability in numerous applications.

Common Applications:

Stockpiling

Ship Loading

Barge Loading Unloading

Heap Leach

Bin & Bunker Loading

Transloading

Powering Utah’s Largest Aggregates Operation

Modern conveyors are so much more than steel structures and rubber belting. They’re smarter than that!

It’s this new technology that separated the TeleStacker Conveyor from others and cause an industry veteran to say: “I want that one!”

Production Advantages

01.

Desegregates Stockpiles

To operations where segregation is an issue, TeleStacker Conveyors prevent deduct penalties and save costs with restoring in-spec material.

02.

Higher Volume Piles

Our automation fills out the back of a stockpile, resulting in 30% more material on the same footprint.

03.

Easy Automation

Designed in-house – which means faster support when you need it – our PilePro Automation is easy to set up and simple to operate.

04.

User-Friendly UPkeep

A Slidetrack System that won’t collect fugitive material, plus a winch placed in the stinger to avoid getting buried by material.

Local Stock. Local Support. Local Experts!

395,000

Maximum

Pile Volume

in Tons

5,000

Maximum

Production Rate per hour in Tons

1,800

Units

Manufactured

to Date

1997

First Unit Sells

and It’s Still

Operating Today!

210

Length of

Longest Unit

in Feet

12

Patented

Technologies

Safety Advantages

01.

Heavyweight Champion

A heavy-duty design means we’ve got a deeper truss, a robust undercarriage, and more cross bracing.

02.

FB® Undercarriage

Patented design provides maximum undercarriage support for safety and lateral stability.

03.

Stinger Safety Stop

Continuously monitors cable tension to stinger conveyor. Automatically activates if cable breaks.

04.

Stinger Load Rollers

Each large diameter roller equally shares the weight of the stinger conveyor.

Videos

This 8-minute long video is the most detailed visual guide to the features, benefits, functions, and options for the TeleStacker Conveyor.

The brains of the TeleStacker Conveyor is its PilePro Automation. Here’s a step-by-step guide to how the program creates high volume piles.

Once Coram Materials replaced their trucks with TeleStacker Conveyors, their operations simply started making more money!

Common Axle Configurations

FD Axle

FD Axle with Auto Level Technology

XTP Swing Axle

Chain-Free XTP Swing Axle

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | TeleStacker Conveyor

See our privacy policy.