Ocean Terminals

Portable ship loading technology requires versatility to serve a variety of vessels, mobility to move throughout the deepwater ports and flexibility to handle a variety of dry bulk materials.

Opposed to costly stationary ship loading systems, custom-configured mobile conveyors from Superior deliver lower capital investment, short lead times, quick assembly and mobility on a small footprint.

Customer Stories

VIDEO: Mobile Ship Loading Conveying Equipment

As an alternative to costly stationary ship loading systems, custom-configured mobile loading/unloading conveyors deliver lower capital investment, shorter lead times, and ease of relocation and efficiency within a small footprint.

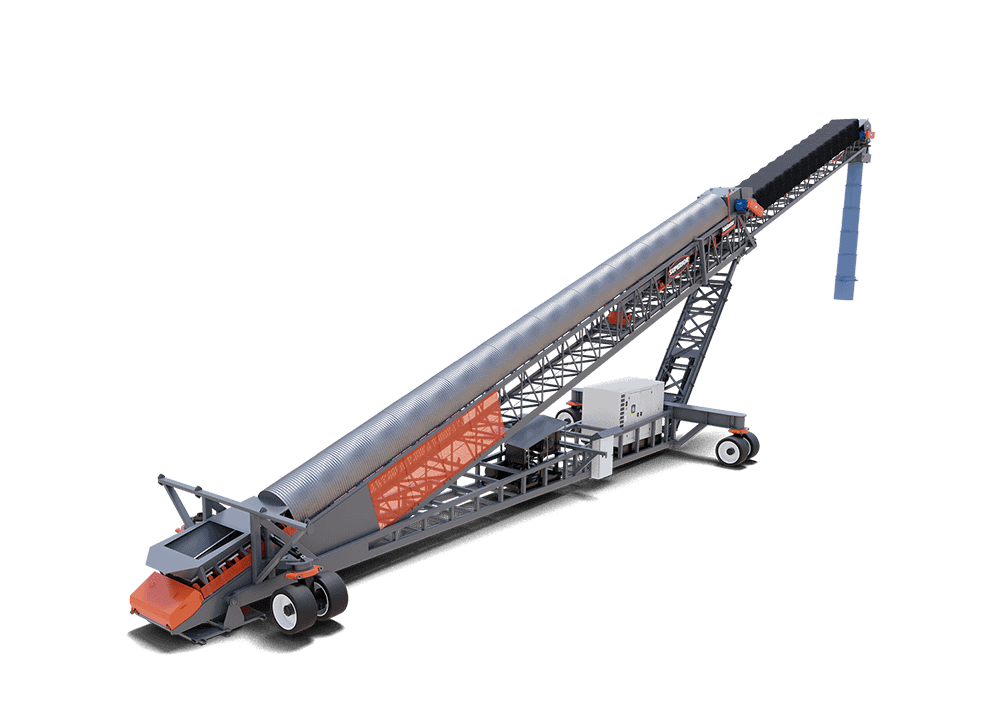

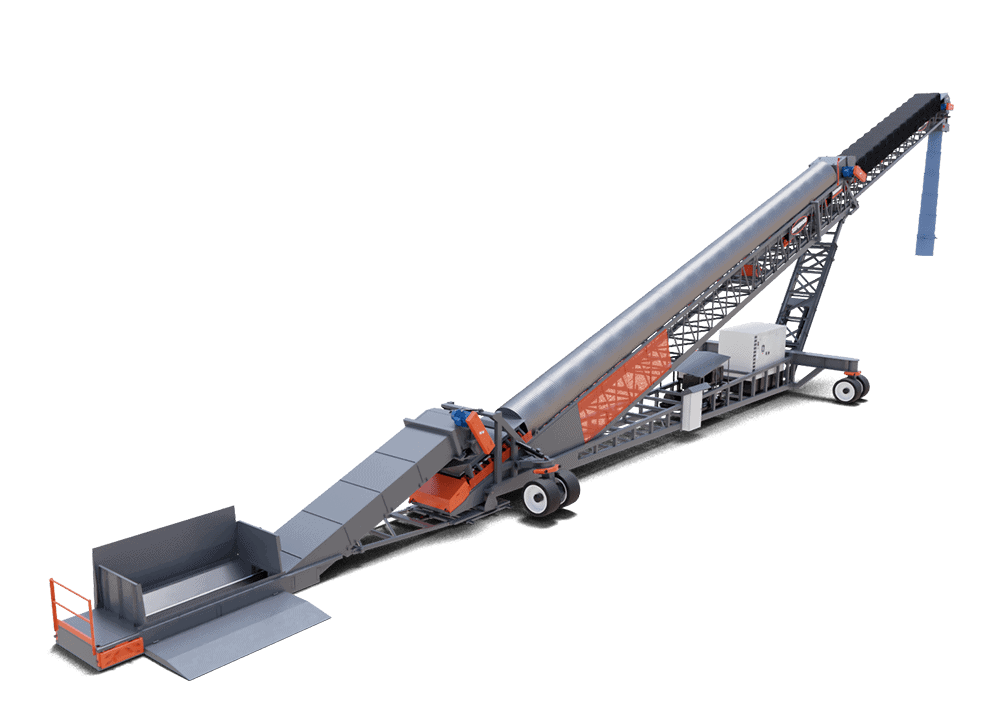

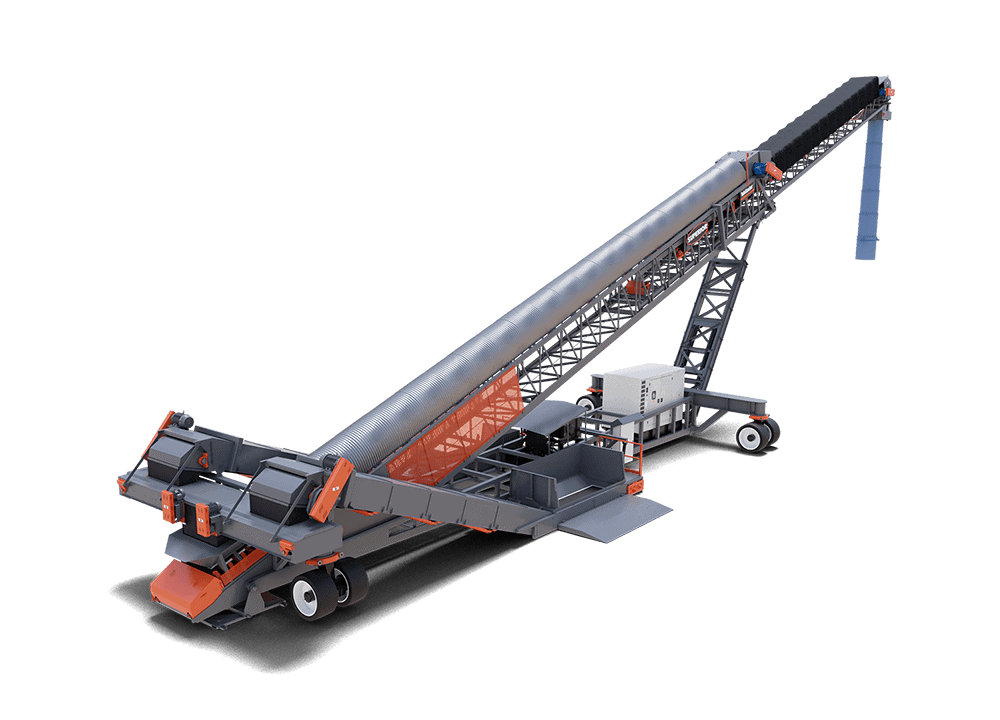

telestacker conveyor

Ship Loading Models

New self-contained models for remote quarrying and mining sites.

Standard »

Why Invest in Mobile Dry Bulk Handling Solutions?

Significantly lower capital investment than highly-engineered, fixed systems.

Faster lead times compared to fixed systems requiring excessive engineering.

Installation times measure in hours and days versus weeks or months.

Small footprint creates more dock space for other opportunities.

Highly mobile conveyors rapidly move in and out of your operation.

Multi-functional machinery performs loading, unloading and stockpiling tasks.

Superior’s portable conveyors have high resale value, even increasing over time.

Quality of bulk material maintained throughout the conveyor handling process.

Watch an overview of a recently built 210ft TeleStacker® Conveyor. The engineering and product team set it up for operation on the test pad, a prerequisite before final ship-out to the end customer.

In Washington, a dual lane RazerTail® Truck Unloader is paired with a series of jump conveyors which ultimately discharge to a TeleStacker® Conveyor. The TeleStacker Conveyor is designed to load both ships and barges.

In North Charleston, South Carolina, Carver Companies constructed a brand new container port. Learn how the team at Carver use a Zipline® Conveyor, (3) TeleStacker® Conveyors and a Trailblazer® Portable Groundline.

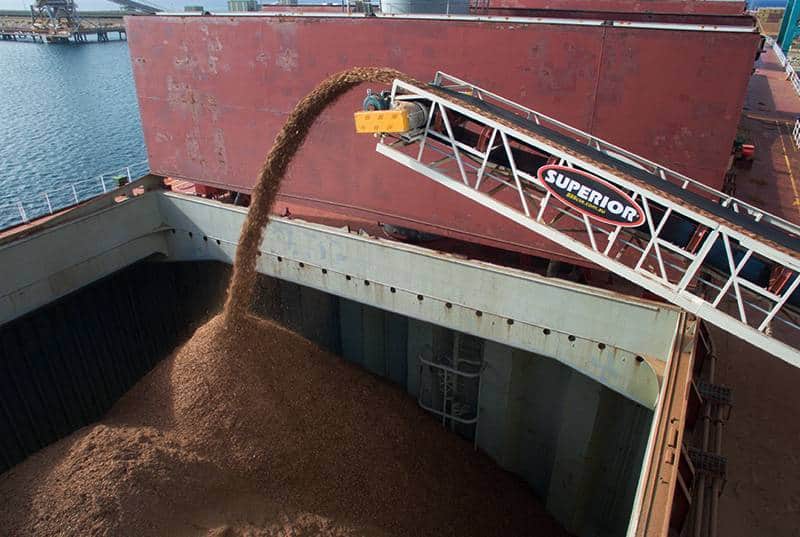

Located in Jacksonville, FL these four Superior machines work around the clock to load this vessel full of wood chips to be delivered to Turkey.

Woodville Pellets Takes Advantage of Ship Loader Mobility

Any maneuverability barriers at the dock are defeated thanks to a fully-mobile, self-contained new Ship Loading TeleStacker® Conveyor recently commissioned by Woodville Pellets . Watch to learn how many holds they can hit without relocating the ship or conveyor.

image Gallery

ocean terminal operations

featured equipment

TeleStacker® Conveyor

Continuously feed multiple hatches from the same feedpoint

Achieve up to 45% more extension than some competitive conveyors

Move inline, transversely and radially for fast and efficient relocation.

Load, unload and stockpile with a single machine

Maintain tight spec of material from ship to stockpile.

Highest capacity radial telescopic conveyors on the planet.

featured equipment

RazerTail® Truck Unloader

Unload belly dump, end dump or side dump trucks.

Transfer dry bulk to ship loading equipment to avoid double handling.

Truck cycle times as low as two minutes.

Patented self-cleaning ramps dump overflow material to hopper.

Quickly transition from mobile to working mode in minutes.

more Conveying equipment

Have questions? Need a quote? Complete the form below and we will follow up shortly.