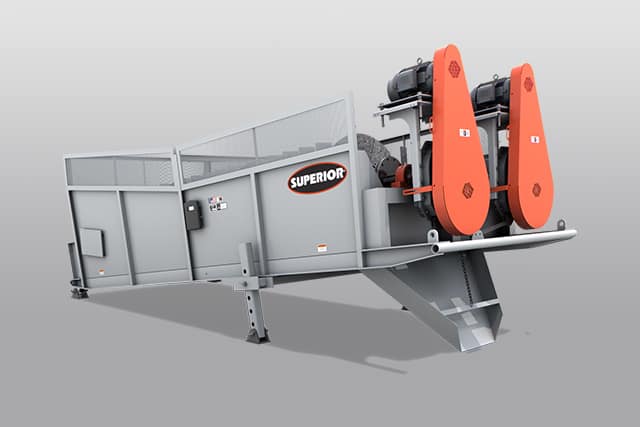

Coarse Material Washer

Remove Unwanted Material

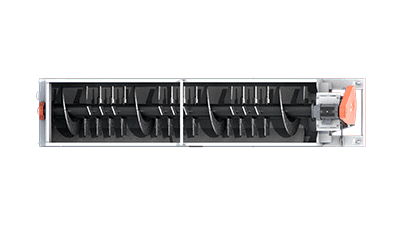

Built to withstand rugged conditions, our Coarse Material Washer will remove clay, dirt, vegetation, dust, and other rock coatings that cannot be removed by wet screening alone. In aggregates, coarse is usually defined as 3/8” to 3.5” (10 – 80mm).

These washing screws also aid in separating fine particles from the coarse aggregates. The combination of water and paddles agitate the material, allowing sand and other small particles to separate and be carried away as slurry.

By removing impurities, Coarse Material Screws contribute to the production of high-performance concrete and asphalt mixes.

Applications:

Asphalt

Concrete

Crushed Stone

Industrial

Recycled Materials

Road Base

Sand & Gravel

Advantages

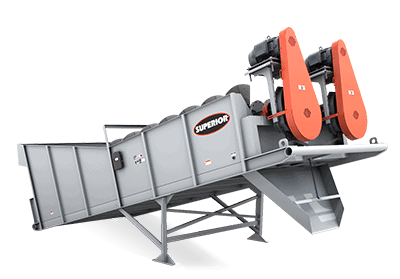

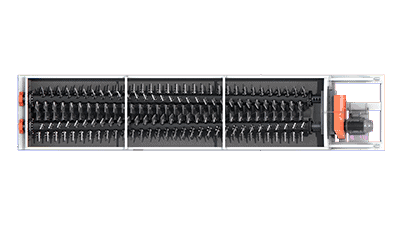

01.

Skidded Frame

Adds rigidity to the machine so that its shape stays solidly square during installation and operation.

02.

Belly Pan

A curved design eliminates dead spots while a flush back nozzle enhances the material cleaning process.

03.

Overflow Gate

Adjustable feature allows control of water bed depth for a cleaner, drier product.

04.

Drive System

Utilizes an off-the-shelf, shaft-mounted gear reducer that is fully-guarded during manufacturing.

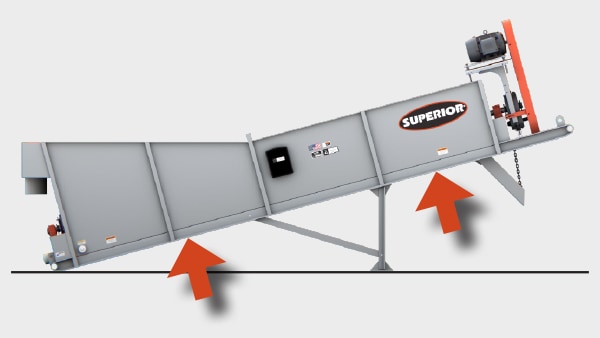

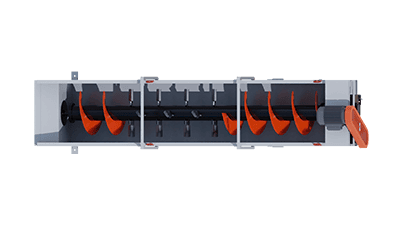

How Does A Coarse Material Washer Work?

Material is fed into the inlet of the tub as water is introduced through spray bars or nozzles. The water loosens and suspends unwanted materials.

As the material and water move along the length of the screw, shaft-mounted flights and paddles provide mechanical agitation. This action breaks up clumps, dislodges contaminants, and allows the water to thoroughly mix with the material.

Unwanted and finer materials form a slurry and are carried out the back end, while the cleaner and coarser material moves along the screw and discharges at the opposite end.

Comparing Screw-Based Washers

Coarse Screw

Primary Function

Removes sand, slime and dust from gravel

Bonus Benefit

Improves effectiveness of screening

Feed Characteristics

Dry or wet

Moisture At Discharge

10-30%

Fine Screw

Primary Function

Wash sand

Bonus Benefit

Dewatering and some surface cleaning

Feed Characteristics

Slurry

Moisture At Discharge

15-25%

Log Washer

Primary Function

Remove plastic clays from rocks

Bonus Benefit

Reduce deleterious materials

in feed

Feed Characteristics

Usually dry

Moisture At Discharge

10-30%

Blade Mill

Primary Function

Convert dry feed into slurry for screening efficiency

Bonus Benefit

Remove lightweight organic particles

Feed Characteristics

Dry

Moisture At Discharge

40%

Local Stock. Local Support. Local Experts!

Coarse screws are included in Lyman-Richey’s compact washing plant.

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Coarse Material Washer

See our privacy policy.