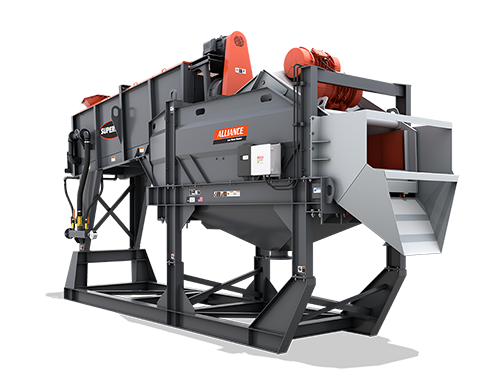

Alliance® Low Water Washer

Convert Crusher Dust to Profit

The Alliance Low Water Washer combines a specially-designed agitator and a dewatering screen into one machine. Most uniquely, it accepts a dry feed, which allows operators to wash rock fines within the crushing circuit and produce a high value manufactured sand.

As natural aggregate becomes more scarce, demand for manufactured sand is growing around the world. Therefore, producers are looking for new fines management tools to recover the most capital from their crusher dust.

Owners of Superior’s innovative low water washing system are no longer forced to truck or transport their crusher fines to a separate wash site — a historically expensive journey with lots of rehandling!

Applications:

Manufactured Sand

Crusher Dust / Fines

Concrete Sand

Water Deficiency

Low Water Sand Processing

6 Things You Must Know

How do you become water-wise? How do you practice and maintain low water sand processing?

Based upon the expertise of veteran mineral wet process guru, John Bennington, we’ll outline the six biggest things you must know about low water sand processing.

Sustainable Answer to Water Scarcity

As natural resources dwindled, the local government put the clamps on water usage at Rilite Aggregates. Integrating an Alliance Washer into the plant substantially reduced water consumption.

Advantages

01.

Agitator Section

Accepts a dry feed directly from the crushing circuit, some water is added, and a thick slurry is created.

02.

Spray BArs

As material is transferred to the dewatering screen, multiple spray bars break up the feed and wash out unwanted fines.

03.

Dewatering Screen

Dewatering occurs as the material passes the screen media and the discharged product has about 8-12% moisture content.

04.

Water EFficient Production

Compared to traditional screws, the low water washer requires up to 80% less water to process crusher fines.

Local Stock. Local Support. Local Experts!

Videos

Animated overview of Alliance Low Water Washer features.

Team Elmers no longer transports fines to a separate wash site and uses 90% less water to clean their product.

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Alliance Low Water Washer

See our privacy policy.