Drum Pulleys

Winners Circle

Drum pulleys are one of the most versatile components of a conveyor system. Depending on their specifications, they can serve in a variety of roles or positions, including drive or head, return or tail, bend tensioning, snub tensioning and/or take-up pulleys, which increase or decrease the amount of slack in your conveyor belt.

Maximum pulley life is essential to cost-efficient material handling and high-capacity production. Importantly, a manufacturer’s approach to pulley design, manufacturing and proper application has a direct effect upon pulley reliability or potential pulley failure.

Advantages

01.

Welding Expertise

Inside our own weld training center, our welding team is trained and certified to AWS D1.1 standards.

02.

In-House Testing

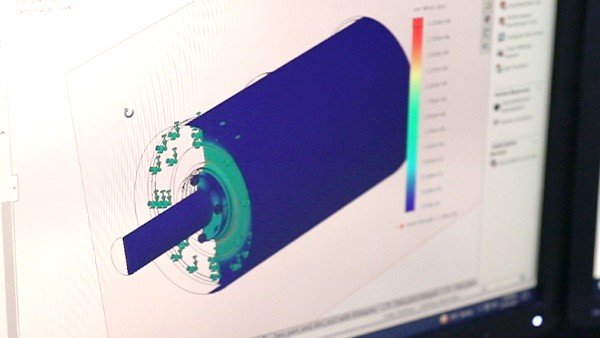

Superior conducts its own testing to assure safe, reliable and cost-effective performance.

03.

Pulley Engineers

Pulley-specific engineers work with customers on analysis, application sizing and recommendations.

04.

Expedited Deliveries

Local distribution, elite welders, in-house testing and vulcanization all contribute to expedited deliveries.

Next Generation Pulley

Prime Pulleys

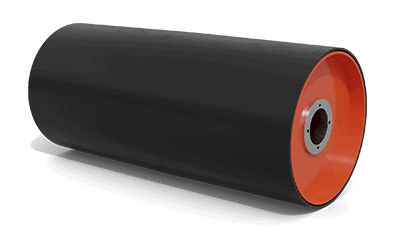

Prime® Pulleys are the newest addition to Superior’s conveyor pulley portfolio. They combine the best of modern engineering practices with redefined manufacturing techniques.

It’s not too light — which can be a disadvantage of CEMA Duty drum pulleys — but it’s not too heavy either. Frankly, Mine Duty model drums can be overkill sometimes. In many applications, Superior’s new Prime Pulley is just right.

How do you know if the Prime Pulley is right for you?

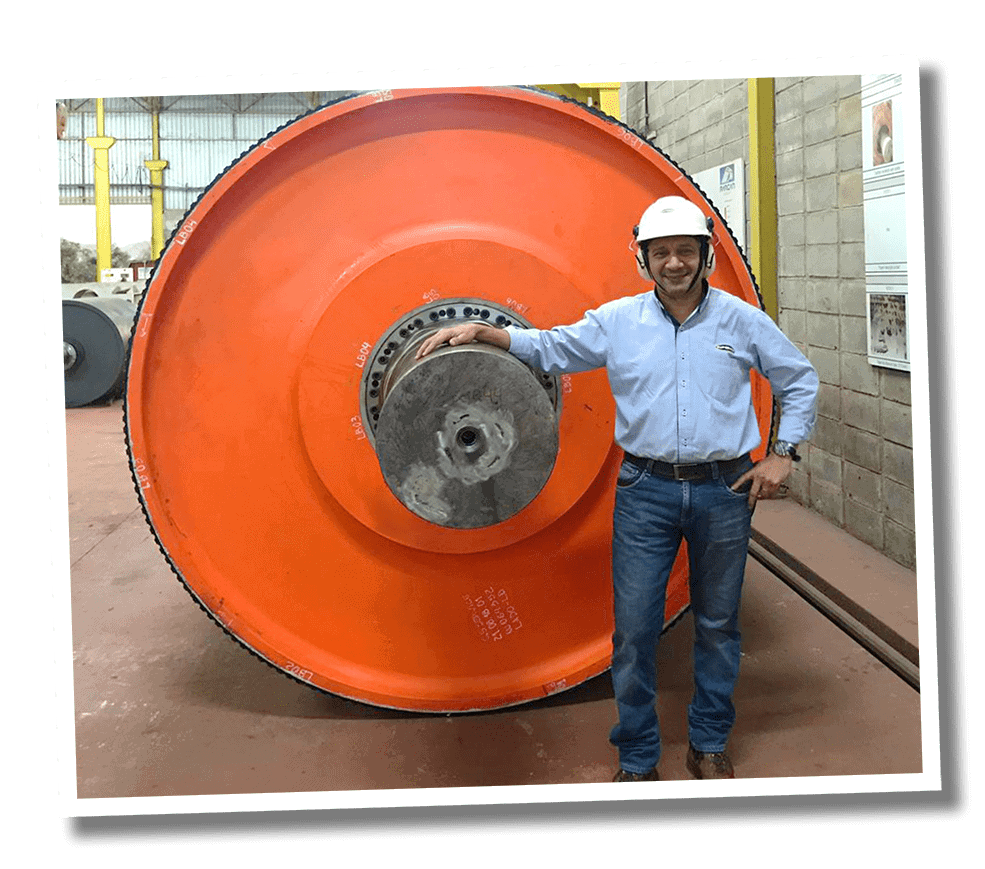

Larger Than Life

drum pulley manufacturing

From our manufacturing plants in South America, we supply mission-critical mining operations with some of the largest, highest capacity conveyor pulleys on planet Earth!

Drum Pulley

class ranks

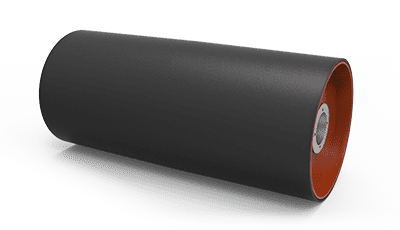

CEMA DUTY

APPLICATIONS:

Uniformly-loaded fabric belts with infrequent starts and stops.

DIAMETER:

8” – 60”

203mm – 1,524mm

FACE WIDTH:

12” – 78”

305mm – 1,980mm

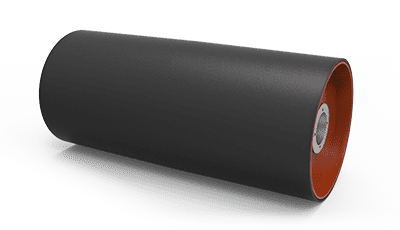

Prime DUTY

APPLICATIONS:

Fully-loaded fabric belts with frequent starts and stops.

DIAMETER:

8” – 60”

203mm – 1,524mm

FACE WIDTH:

12” – 78”

305mm – 1,980mm

*Prime® Duty

Mine DUTY 2.0

APPLICATIONS:

Fully-loaded fabric belts with frequent starts and stops.

DIAMETER:

8” – 60”

203mm – 1,524mm

FACE WIDTH:

12” – 78”

305mm – 1,980mm

super DUTY

APPLICATIONS:

Fully-loaded fabric belts with frequent starts and stops.

DIAMETER:

8” – 60”

203mm – 1,524mm

FACE WIDTH:

12” – 78”

305mm – 1,980mm

engineered class

APPLICATIONS:

Custom designed pulleys often used with steel cable belts.

DIAMETER:

Custom

FACE WIDTH:

Custom

Drum models

Standard

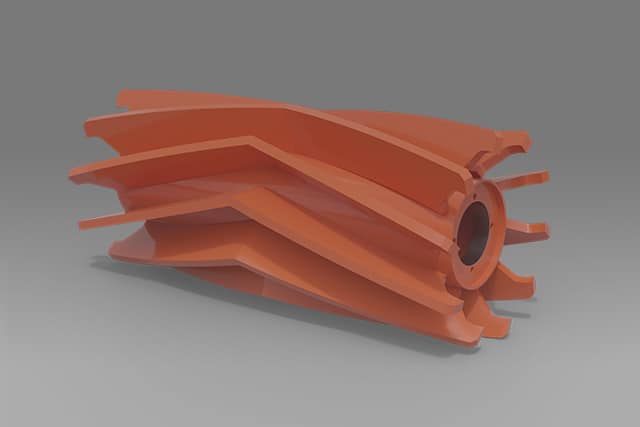

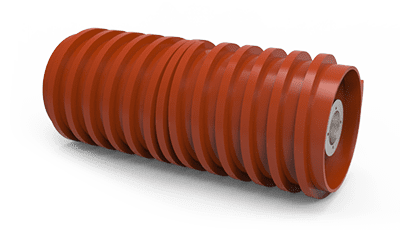

spiral drum

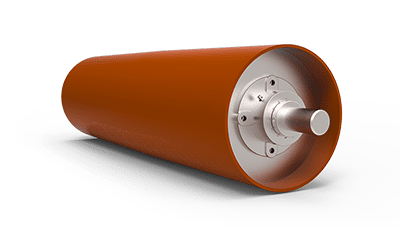

dead Shaft

Single Disc

Back to top »

Drum Lagging options

smooth

chevron

herringbone

diamond

Weld-on/slide

ceramics

Arrowhead ceramic

urethane

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Drum Pulleys

See our privacy policy.