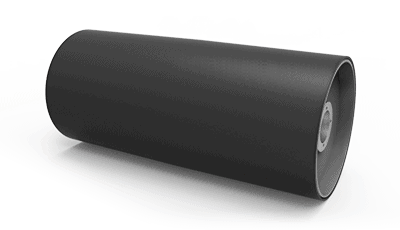

Prime® Pulley

Prime Pulleys are the newest addition to Superior’s conveyor pulley portfolio. They combine the best of modern engineering practices with redefined manufacturing techniques.

NEXT GENERATION Pulley

It’s not too light — which can be a disadvantage of CEMA Duty drum pulleys — but it’s not too heavy either. Frankly, Mine Duty model drums can be overkill sometimes. In many applications, Superior’s new Prime Pulley is just right.

How do you know if the Prime Pulley is right for you?

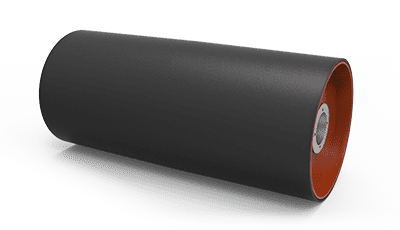

FIVE Benefits of the Prime Pulley

Fewer Welds

An integral hub is machined from a solid piece of steel and eliminates welded joints.

Cost Savings

Are you upgrading to big-ticket, extra heavy-duty construction when you don’t need to?

Less Inventory

It’s a single model capable of performing in multiple applications.

Reduced Weight

This is the result of modern engineering, which positions the weight where it should be.

USA Steel

We still use steel manufactured in America and we still think it’s better!

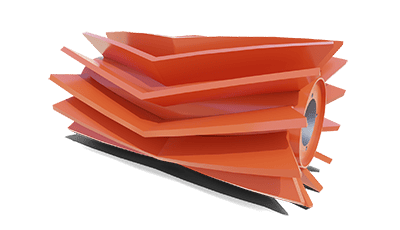

Protect Your Rights!

Chevron® Wing Pulleys fend off fugitive material.

How Conveyor Drum Pulleys Compare

SUPERIOR

CEMA DUTY

PRICE

$$

DURABIILTY

**

WEIGHT

334 LBS

RIM THICKNESS

1/4″

AVERAGE END DISC THICKNESS

1/2″

HUB CONSTRUCTION

WELD-IN

SUPERIOR

Prime® DUTY

PRICE

$$

DURABIILTY

***

WEIGHT

402 LBS

RIM THICKNESS

1/4″

AVERAGE END DISC THICKNESS

1-1/4″

HUB CONSTRUCTION

INTEGRAL

SUPERIOR

Mine DUTY 2.0

PRICE

$$$

DURABIILTY

****

WEIGHT

575 LBS

RIM THICKNESS

3/8″

AVERAGE END DISC THICKNESS

1-1/4″

HUB CONSTRUCTION

INTEGRAL

PPI

Pro series*

PRICE

$$

DURABIILTY

***

WEIGHT

344 LBS

RIM THICKNESS

1/4″

Comparative specs for 16×57 Drum Pulley with XT40 Bushings

*PPI and PRO SERIES are trademarks of their respective owners. Use of those marks is for informational purposes and does not imply endorsement or affiliation between those owners and Superior or any of its affiliates.

Connect with a pulley specialist

Connect with a pulley specialist and help decide if the Prime Pulley is right for you!

See our privacy policy.