Morris, Minn. – Superior Industries, Inc., a US-based manufacturer and global supplier of bulk material processing and handling systems, is planning to showcase more than 250-tons of its products at CONEXPO-CON/AGG 2023. At least eight of the products will be brand-new and revealed for the first time at the show next spring in Las Vegas, Nevada.

For previous CONEXPO-CON/AGG attendees, Superior wants you to know about its new booth location for the 2023 edition of the show. The manufacturer is relocating from inside Central Hall to outside in the Silver Lot.

“Inside is climate-controlled and comfortable, but our equipment and our people were born to be in the great outdoors!” says Corey Poppe, Superior’s communications manager. “In addition to our massive display of equipment, we’re incorporating lots of fun elements that only work in the open air. Things like 20,000 square feet of artificial turf, grilling and grill giveaways, laid back patio-style seating, and maybe we’ll even roast a few marshmallows!”

Here’s a brief preview of some of the products Superior plans to showcase:

Expanded Cone Crusher Portfolio

Two brand-new cone models will be introduced and be shown alongside Superior’s trusted Patriot® Bushing Cone. First, the Dakota™ Bearing Cone, which will earn credibility for its efficient use of horsepower per ton, a straightforward lubrication system, and a wide range of liner profiles. The other new cone crusher will be called the Endeavor™ Spider Bushing Cone. Operationally, it’s an uncomplicated design that accepts a wide range of feed sizes with an adjustable stroke for fine tuning. Superior also plans to display its Liberty® Jaw, Valor® VSI, and Sentry® HSI crushers.

New Portable Plant Utilized in Recycling – Download Picture

Designed to process in recycle applications, Superior’s says its brand-new Portable Sentry® HSI Closed Circuit Plant will get plenty of attention under the Vegas sun. It’s equipped with a patent pending recirculating conveyor, which centralizes the crusher feed for full utilization and extended wear life of the HSI’s blow bars. Other highlights include application-specific grizzly configurations, interchangeable cross conveyors, and screen media below the grizzly section.

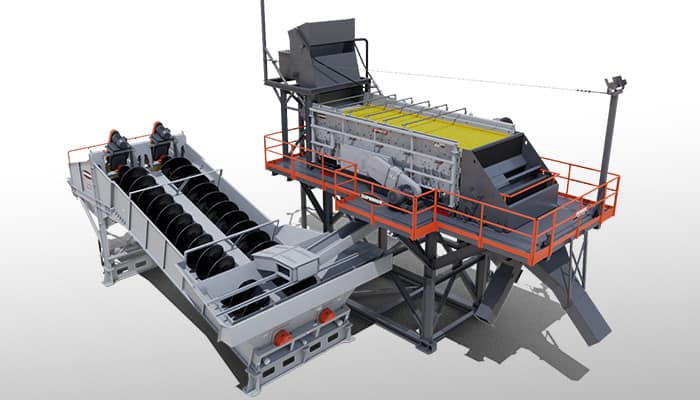

New Quick to Erect Modular Wash Plant – Download Picture

According to Superior, its increasingly broad portfolio of Fusion® Modular Platforms are a good match for aggregate producers seeking semi-static plants that are easy to install and maintain with a more economical price tag than portable plants or design-build projects. On display, the company plans to erect a 8×20, 3-deck Guardian® Horizontal Wet Screen Fusion Platform with an Aggredry® Dewatering Screen attached to one of the discharge points.

Telescopic Stacker Builds 200,000-Ton Stockpiles – Download Picture

In 2023, it will mark the eighth time Superior will display its famed TeleStacker® Conveyor at CONEXPO-CON/AGG — and each show there is new technology to showcase and new success stories to share. With radial travel, variable height and a telescopic conveyor, TeleStacker Conveyors stockpile material in a way that overcomes material segregation. This show, Superior will display a 42” x 170’ XTP Swing Axle model with a working automation panel that visitors can interact with in the booth.

Conveyor Components to Reduce Maintenance Duties – Download Picture

Once again, Superior will display a wide variety of its own conveyor components. In fact, the manufacturer is planning to show more than three dozen individual idlers, pulleys, scrapers, and other conveyor accessories. New products include a redesigned line of Exterra® Belt Cleaners with some brand-new options, a modular Load Zone Skirting System for dust and spillage control, and unique Application-Specific Idler Bearing Seals for longer-lasting idlers in demanding conditions.

Superior Industries booth will be located in the Silver Lot, right inside what’s traditionally been known as the main entrance to the show. The booth number is S-5006. In the coming days, a set of web pages dedicated to presenting Superior’s experience at CONEPXO-CON/AGG.