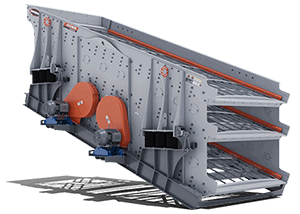

Anthem® Inclined Screen

Gravity-Based Rock Sizing

With robust construction and advanced screening mechanisms, the Anthem Inclined Screen ensures superior material separation, reduced downtime, and increased productivity.

Anthem Screens are typically used in fine and coarse screening applications or for operators requiring a scalping stage, which removes oversized materials before the crushing or processing circuit.

Standard duty applications include a 2-bearing, single shaft design, while 4-bearing dual shafts are manufactured for the most demanding requirements.

Applications:

Ore/Hard Rock Mining

Quarried Stone

River Gravel

Recycled Concrete

Fractured Gravel

Cubicle Products

Super Pave Products

Shaker, Shaker, Money Maker!

Josh has worked with lots of screens during his career, but Superior’s Anthem Inclined Screen offers a unique feature the others don’t.

Advantages

01.

Deck Spacing

Additional room between decks allows space for maintenance crews to change out media more comfortably.

02.

Modern Spring Arrangement

Surge dampening calms start up and shut down, while bottle jack lifting points simplify maintenance.

03.

Integrated Feedbox

Integrated into the frame of the screen with bolted wear liners and deflector plates for trouble free operation.

04.

Fabricated I-Beam

Creates the highest strength-to-weight ratio so you can put more rock shaking action into your screens.

How Does An Inclined Screen Work?

Unlike horizontal screens, which require high amounts of energy to move material, inclined vibrating rock screens take advantage of gravity.

They operate at angles of 15° – 20° and rely on a circular motion (and gravity) to move material down the decks and through the media.

They accept a continuous feed of material well and generally deliver at lower costs per ton than horizontals.

Inclined vs Horizontal Screens

Inclined Screens

Uses gravity to move material

Typically lower capital expenditure

Processes higher capacities

Usually mounted in stationary plants

Simple design, easy to operate

Horizontal Screens

Uses oval throw to move material

Most accurate particle sizing

Accommodates heavier bed depths

Low height is great for portability

More complex drive system

SEE GUARDIAN® HORIZONTAL SCREENS »

Local Stock. Local Support. Local Experts!

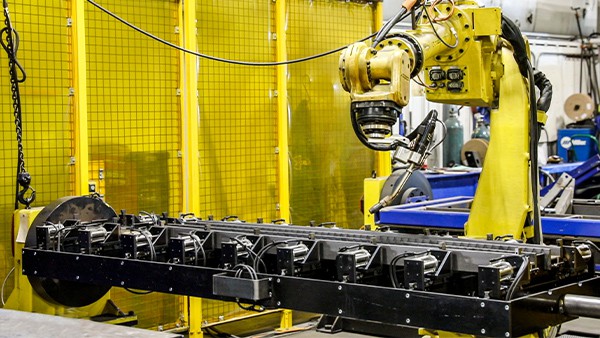

Our product manager reviews the features of Superior’s incline screen.

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

REQUEST MORE INFO | Anthem Inclined SCREEN

See our privacy policy.