Superior Idlers

reliable foundations

Idlers are to conveyors as foundations are to buildings: constant, reliable support.

For proper operation, idlers need a sophisticated seal to protect their bearings in all conditions. Second, conveyor owners need a variety of models and options to handle and endure application-specific environments. Third, idler consumers require a modern manufacturer who is built to respond quickly.

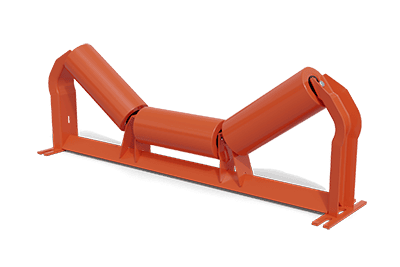

Steel Rolls

A full offering of CEMA rated rolls and frames, plus other unique models for the most complete idler offering of any manufacturer in the world.

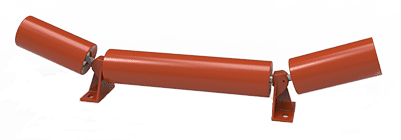

Rubber Rolls

In a troughing position, rubber idlers are typically utilized at the tail end of the conveyor, because they can absorb any shock caused by falling material.

Moxie® Rolls

These energy efficient, material-shedding rolls are manufactured using a specially formulated high-density polyethylene.

Urathon® Rolls

The modern properties of polyurethane always outlast and outperform old-fashioned elements like steel or rubber.

40 Series idlers

A domestic source for idler configurations common to European-designed track mounted crushers and other small processing equipment.

beater bars

The rods create a beating motion in the belt, and gaps between the bars allow for material to escape to prevent buildup.

Have questions? Need a quote? Complete the form below and we will follow up shortly.

Request More Info | Superior Idlers

See our privacy policy.