Resources

Explore tools to help owners and operators solve problems, improve performance, and get more out of their products.

Sorry!

No items currently match your filtering criteria.

Need a Manual Not Listed Here?

Some of our standard product manuals are available on this page, but since most equipment is custom-built, many manuals aren’t listed. Complete this form to request the specific manual for your product and we'll get it to you fast.

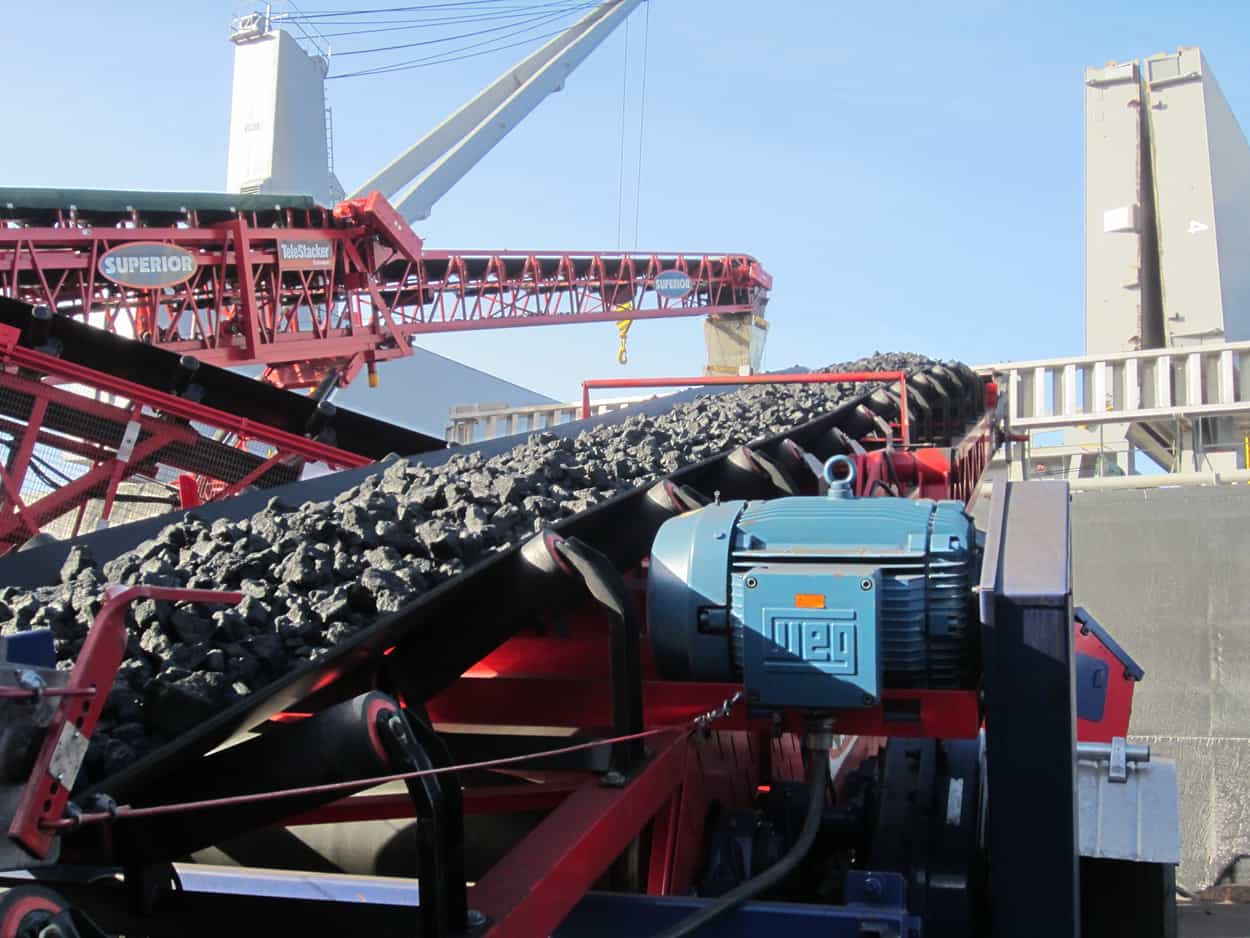

Port & Portability: BCE Boosts Flexibility with Mobile Shiploading System

The Challenge

Bulk Conveying Equipment (BCE) faced a significant challenge at Port Kembla, one of Australia’s busiest import/export centers. The port required a flexible, cost-effective, and highly mobile ship loading system to handle a wide range of bulk materials, including coal, coke, iron ore, and slag.

The traditional fixed ship loading systems were outdated, costly, and unable to adapt to the varying demands of different vessel sizes and materials. Additionally, BCE needed a solution that could operate within a limited berth footprint and comply with stringent environmental regulations, such as minimizing spillage and preventing stockpiling of materials on the berth.

Equipment- RazerTail® Truck Unloader

- TeleStacker® Conveyor

The Solution

Bulk Conveying Equipment (BCE) deployed a customized mobile ship-loading system from Superior Industries: a 72" RazerTail® Truck Unloader plus two TeleStacker® Conveyors (150' and 170').

The mobile setup rapidly loads 5,000–55,000-ton vessels without major fixed infrastructure. A pivot base enables 360° rotation and quick repositioning. Telescoping conveyors place material precisely to reduce spillage and improve efficiency.

Our system gives us so much versatility and is not limited in any way.

The Results

The implementation of Superior Industries' mobile ship loading system has significantly enhanced BCE’s operation at Port Kembla. The system has achieved higher loading capacities, with BCE now able to load up to 1,200 tons per hour of iron ore and 450 tons per hour of coke, depending on hatch changes and screening requirements.

The flexible and portable design has minimized material segregation, reduced capital equipment costs, and allowed for quick on-site assembly and relocation under a smaller footprint. Additionally, the system’s features, such as ceramic liners, AR steel liners, rubber skirting, and stainless steel underpans, have ensured compliance with regulations, while also protecting equipment from wear and tear.

On-Demand Learning for Aggregate Producers

With seasoned operators retiring and fresh faces joining the crew, OptimizeU delivers interactive, on-demand training in crushing, screening, washing, and conveying—accelerating learning and supporting your path to consistent production.

More Success Stories

We’re Ready When You Are!

Talk to our team or find a dealer near you.