All Products

Sorry!

No items currently match your filtering criteria.

We’re Ready When You Are!

Talk to our team or find a dealer near you.

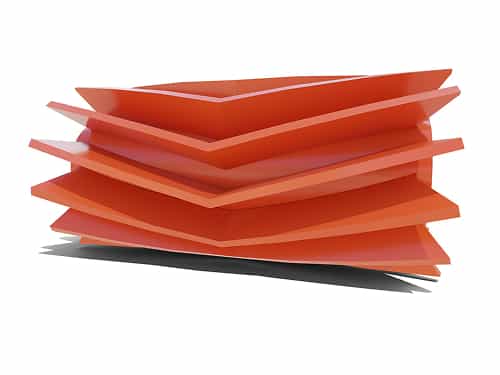

For the Nastiest Material You’ve Got

When clay’s caked on and your deposit is full of trash, a log washer is your best chance at saving the sale. Its rotating shafts and paddles scrub aggressively, breaking down tough clumps and pushing out organics before your screen even sees it.

The Log Washer earns its keep where other machines give up. It’s tough and built to survive the ugliest material your site throws at it. Dirty rock in, clean rock out!

Advantages

Rigid Skid Frame

Allows for easy assembly. Reduces fatigue and increases life of screen. Cuz this is a heavy duty, hard-working machine.

Alloy Steel Parts

Cast iron paddles and shoes deliver wear resistance proven in mining-grade conditions, maintaining consistent washing action over time.

Outboard Bearing

Externally mounted pillow block bearing protects from water and contamination for longer service life and more convenient maintenance.

Adjustable Overflow Gate

Lets operators control slurry level to balance material retention with product cleanliness and dryness.

How Does a Log Washer Work?

A log washer uses aggressive scrubbing to clean clay, mud, and other tough contaminants from rock and gravel. Inside its tank, two counter-rotating shafts fitted with paddles lift and tumble the material, forcing friction between particles to break down sticky clumps.

As the material moves along, heavier, cleaner aggregate sinks and travels up the incline, while lighter waste and fines are carried off the feed end by the flow of water. Adjustable water volume and shaft speed control the level of washing, helping operators dial in the right balance of cleanliness and throughput.

Videos

Watch every stage of a compact wet processing plant — from dredging and screening to classifying, washing, dewatering, and stockpiling — all working together in one seamless flow.

See how one Texas producer invested in a Fusion® Modular Plant built to meet today’s needs and expand easily as demand and production grow.

We're Here to Help

There’s no one-size-fits-all solution. With a few key details about your application, our team will help recommend the setup, system, or component that gets the job done right and keeps things running smoothly.

-

Looking Nearby?

Use our dealer locator to connect with your closest sales representative.

-

Have Others Questions?

Use the form to send us a quick note. We’ll get back to you with answers or next steps.

-

Outside North America?

No problem! We work with partners and customers around the world. Reach out using the form and we’ll connect you with the right person.

20190612_1819.jpg?width=8688&height=5792&name=Lyman%20Richey-Site%20Visit%20(06-2019)20190612_1819.jpg)