All Products

Sorry!

No items currently match your filtering criteria.

We’re Ready When You Are!

Talk to our team or find a dealer near you.

Sort It, Stack It, Move On

For producers handling larger rock and gravel, a coarse screw gets the job done without overcomplicating things. It separates out floating organics and silts while lifting clean material out of the pool and onto your stockpile.

The design’s straightforward and tough, built for big tonnage, with easy access for maintenance. If you're looking for dependable separation without a bunch of extra valves and screens, a coarse screw keeps your process moving without the hassle.

Models

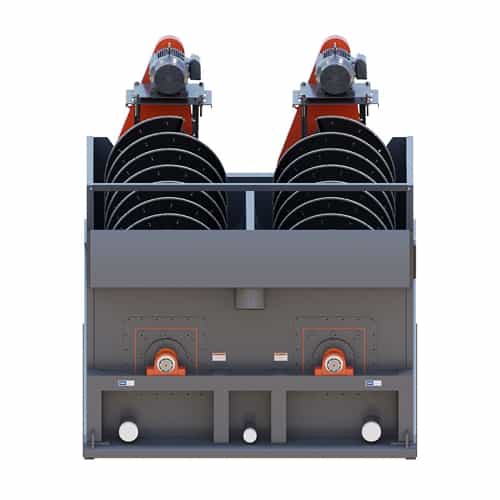

Single Shaft

Rated up to 220 TPH with feed up to 2½ inches, using a single screw configuration and 15–30 HP motor for efficient cleaning at moderate flow rates.

Twin Shaft

Delivers up to 500 TPH with 3-inch feed capability, driven by dual 25–50 HP motors for maximum tonnage and extended retention in demanding operations.

Advantages

Outboard Bearing

Externally mounted pillow block bearing protects from water and contamination for longer service life and more convenient maintenance.

Alloy Steel Parts

Cast iron paddles and shoes deliver wear resistance proven in mining-grade conditions, maintaining consistent washing action over time.

Adjustable Overflow Weir

Fine-tunes pool depth for cleaner sand and improved silt removal in changing feed conditions.

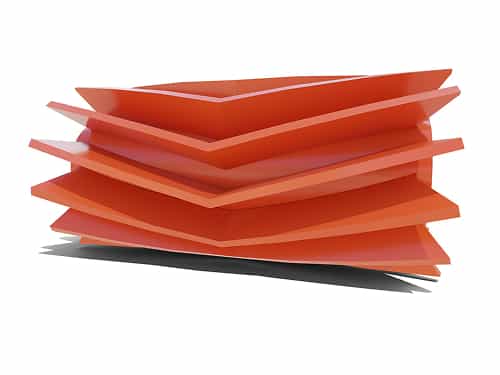

Curved Belly Pan

Eliminates buildup zones common to tubes with 90° angled corners, keeping the washing chamber self-clearing and consistent.

Videos

Watch every stage of a compact wet processing plant — from dredging and screening to classifying, washing, dewatering, and stockpiling — all working together in one seamless flow.

We're Here to Help

There’s no one-size-fits-all solution. With a few key details about your application, our team will help recommend the setup, system, or component that gets the job done right and keeps things running smoothly.

-

Looking Nearby?

Use our dealer locator to connect with your closest sales representative.

-

Have Others Questions?

Use the form to send us a quick note. We’ll get back to you with answers or next steps.

-

Outside North America?

No problem! We work with partners and customers around the world. Reach out using the form and we’ll connect you with the right person.

.jpg?width=3000&height=2000&name=Coarse%20Material%20Washer-Staker%20Parson%20Beck%20Street-Salt%20Lake%20City%2c%20UT%20(2017.05).jpg)