All Products

Sorry!

No items currently match your filtering criteria.

We’re Ready When You Are!

Talk to our team or find a dealer near you.

The Standard for Stockpiling

Producers around the world rely on the TeleStacker Conveyor to build bigger, cleaner, and more consistent stockpiles. The portable telescoping radial stacker is engineered for precise material placement and fully automated pile building that maximizes storage and minimizes rehandling. When uptime and accuracy matter, this machine has earned its reputation for doing both.

Designed, manufactured, and supported by Superior and its team of dealers, the TeleStacker Conveyor combines proven engineering with field-tested controls and components that last. From dry bulk terminals to rugged quarries, it delivers smooth operation, minimal segregation, and stockpiles that stand tall, because you’re running the best-built conveyor in the world.

Models

FD Axle

Hydraulic fold-down axles shift the conveyor from highway travel to radial operation in seconds for true road portability. [Patented]

XTP Swing Axle

Axle arrangement manually swings from inline highway mode to radial mode and radially travels on concrete runway.

Pit Portable Axle

Non-road portable arrangement in which axles pin between transport and radial positions for quick in-pit moves.

Advantages

Anti-Segregation Stacking

Automated radial/telescoping patterns keep fines and coarse where they belong, maintaining in-spec gradations and avoiding penalty deductions.

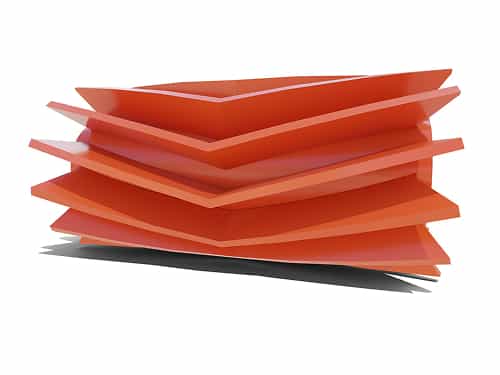

Bigger Piles, Same Footprint

Replaces flat-top stockpiles with a true trapezoid that backfills the rear of the pile, delivering up to 30% more tons on the same pad.

PilePro® Automation Control

In-house engineering means faster support and no third-party reliance — simple setup, self-diagnostics, and smart reminders keep production running and crews confident.

FB® Undercarriage Stability

A wide, fully braced undercarriage resists tipping and sway on uneven pads, improving operator safety and keeping piles uniform. [Patented]

Let the Pile Build Itself

At Fred Weber’s Colorado site, automation takes over once the TeleStacker Conveyor's start their cycle. Each unit runs a preprogrammed pattern to build uniform, desegregated piles with no extra supervision.

Operators set it once, walk away, and come back to perfect stockpiles at the end of the shift. It's proof that well-designed automation can move more tons with less touch.

Where to BuyVideos

See how the FD Axle speeds up setup and teardown, allowing for mobility and flexibility to move from site to site with less downtime.

See how the XTP Swing Axle simplifies repositioning and transport, giving TeleStacker Conveyors faster moves, smoother transitions, and more time on the pile.

Hear from one of Superior's brightest on how PilePro Automation™ builds precise, repeatable piles.

Real Stories, Proven Performance

We're Here to Help

There’s no one-size-fits-all solution. With a few key details about your application, our team will help recommend the setup, system, or component that gets the job done right and keeps things running smoothly.

-

Looking Nearby?

Use our dealer locator to connect with your closest sales representative.

-

Have Others Questions?

Use the form to send us a quick note. We’ll get back to you with answers or next steps.

-

Outside North America?

No problem! We work with partners and customers around the world. Reach out using the form and we’ll connect you with the right person.

20170501_1521.jpg?width=8688&height=4888&name=Staker%20Parson-South%20Weber%2c%20UT-Site%20Visit%20(2017-05)20170501_1521.jpg)

20161207_2431.jpg?width=8688&height=5792&name=Carver%20Company%20-%20Charleston%2c%20SC%20(2016-11)20161207_2431.jpg)