- Crushing

Share This Post

Read the full Tech Tip

Enter your info to access the full article.

Related Topics

Enter your info to access the full article.

Superior’s presence in the VSI crushing market has grown significantly since acquiring the former CEMCO in late 2023. With market share doubling last year, more Superior VSI crushers are starting to show up in the field. That makes this a good time to reinforce the importance of regular inspections and proactive maintenance.

Unlike compression-style crushers like jaws and cones, a VSI relies on continuous, high-speed impact to fracture material. That means wear occurs faster, and even a single neglected component can throw the machine out of balance, leading to severe vibration or structural damage. Regular maintenance isn’t just beneficial for a VSI—it’s essential to keeping it running safely and efficiently.

ITo understand just how critical maintenance is, we spoke with Kyle Ruschmeyer, one of Superior’s boots-on-the-ground crusher service technicians. He’s seen firsthand what happens when VSI maintenance is overlooked.

“Without frequent inspections, worn components can throw the machine out of balance, causing excessive vibration and structural damage,” says Ruschmeyer. “I’ve seen material wear right through the anvils and start cutting into the crusher body itself—turning a simple fix into a major repair.”

“If your customers don’t stay ahead of wear, a VSI will quickly start destroying itself,” he says.

According to Ruschmeyer, well-organized operators inspect their VSI crushers at the beginning or end of each shift to catch wear and misalignment before they cause larger issues. In high-abrasion applications like manufactured sand production or crushing quartzite, inspections may be necessary as often as every four hours.

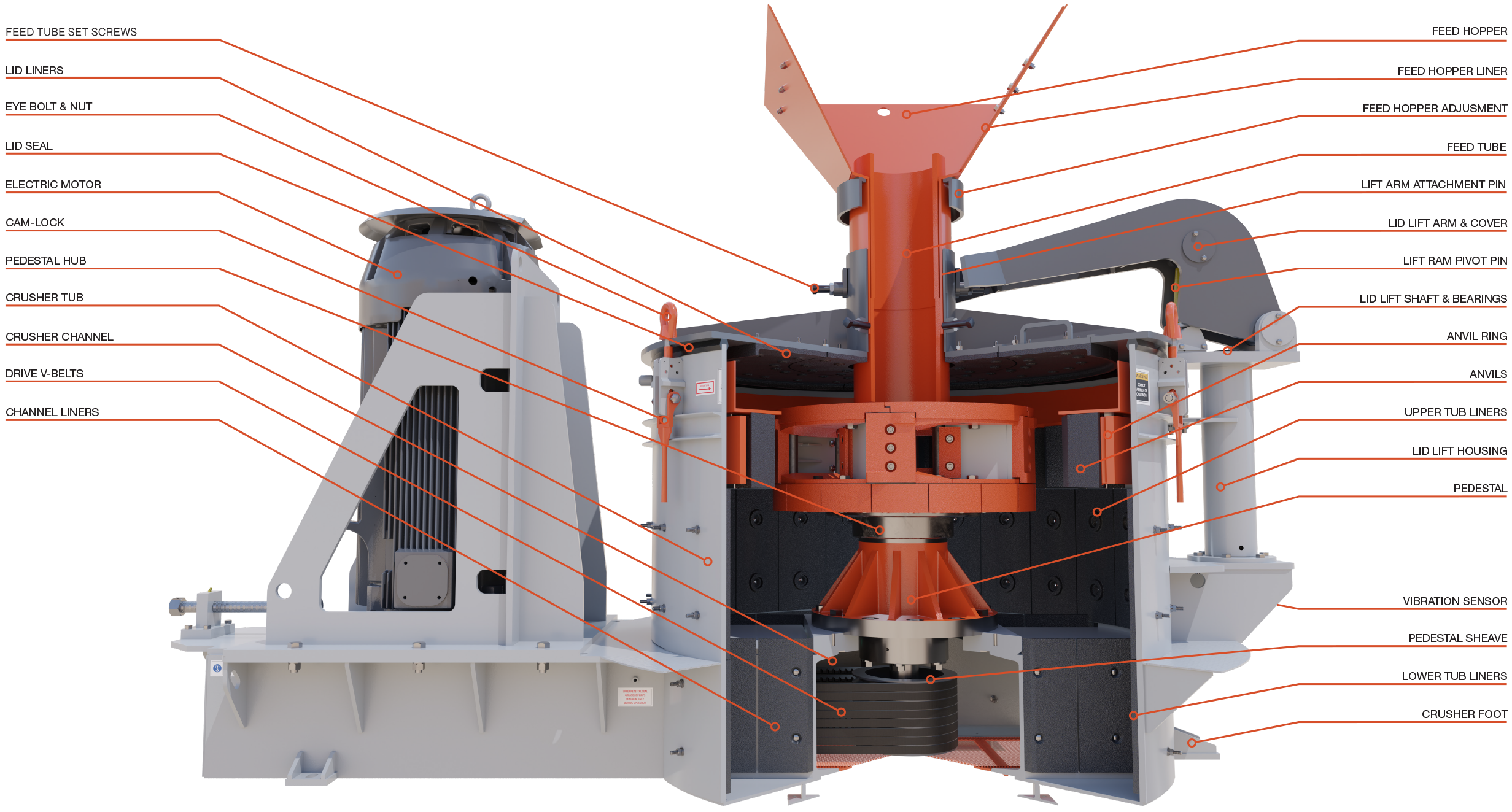

Cemco T80 VSI Components Identification

A well-maintained VSI crusher delivers consistent product quality, reduced downtime, and longer component life. Here’s a breakdown of the critical areas to inspect and what to look for to prevent performance issues and costly repairs.

The rotor is the heart of a VSI crusher, spinning at high speeds to propel rock into wear surfaces. An unbalanced or worn rotor can cause excessive vibration, reduced efficiency, and structural damage.

The high speed operation of VSI’s places a significant load on the bearings. Proper lubrication is critical to preventing premature wear, overheating, and catastrophic bearing failure.

The crushing chamber is where rock fractures upon impact. VSI crushers use either anvil rings (rock-on-steel) or rock shelves (rock-on-rock) for material reduction.

The feed system controls material entry into the rotor. Blockages, misalignment, or excessive wear can disrupt crushing performance.

A destroyed rotor caused by an over-torqued bolt that snapped, allowing a feed disc to bounce freely during operation.

Regular VSI inspections may take time, but the cost of skipping them is far greater.

“It doesn’t take much – one worn part left unchecked – and suddenly your customer has a bigger problem on your hands,” says Ruschmeyer. “A few minutes of inspection can prevent days of downtime and thousands in repairs.”

Staying ahead of wear doesn’t just extend VSI life, it keeps production on track and prevents shutdowns that cut into profitability.

Talk to our team or find a dealer near you.