Conveyor monitoring

in real time. All the time.

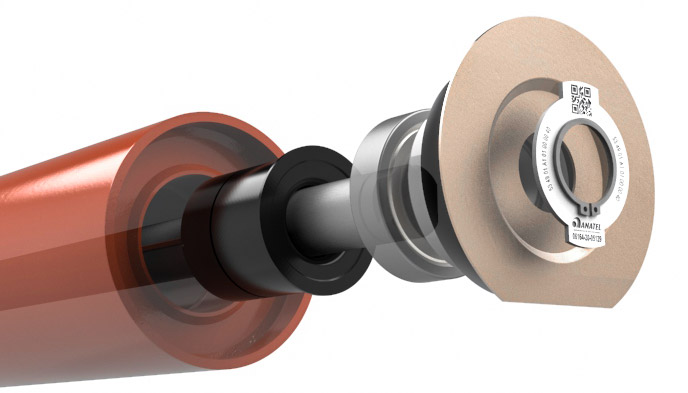

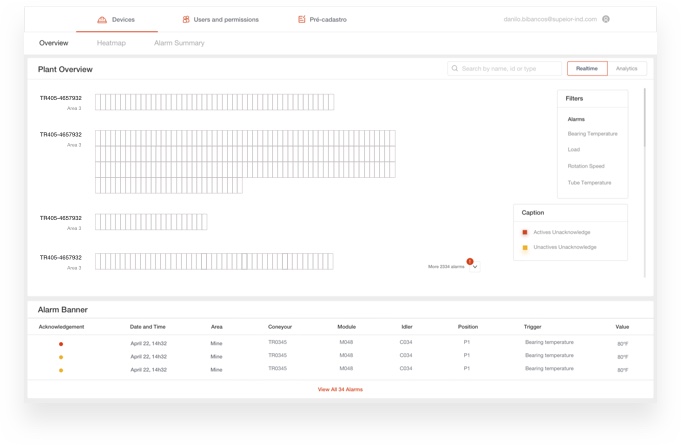

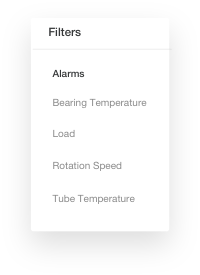

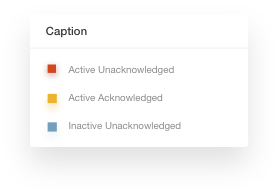

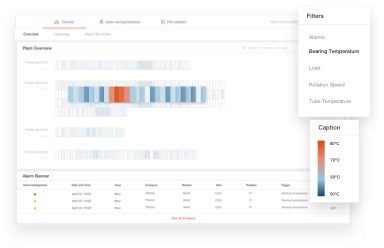

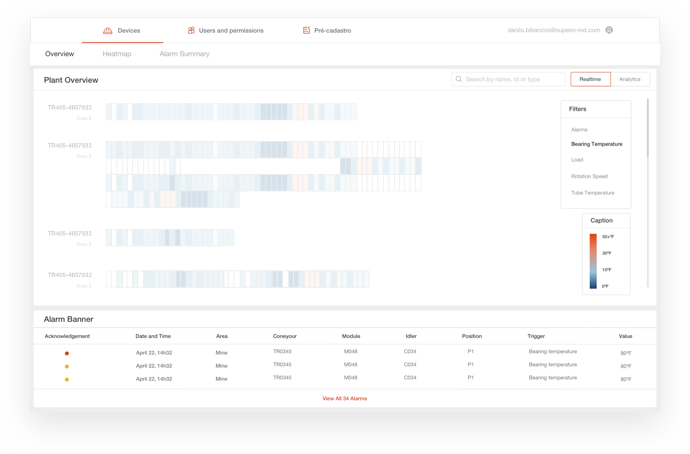

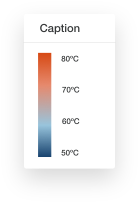

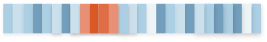

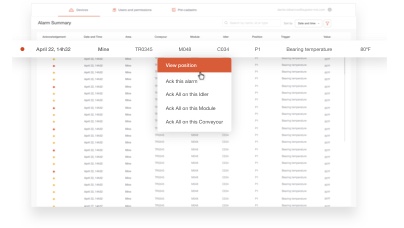

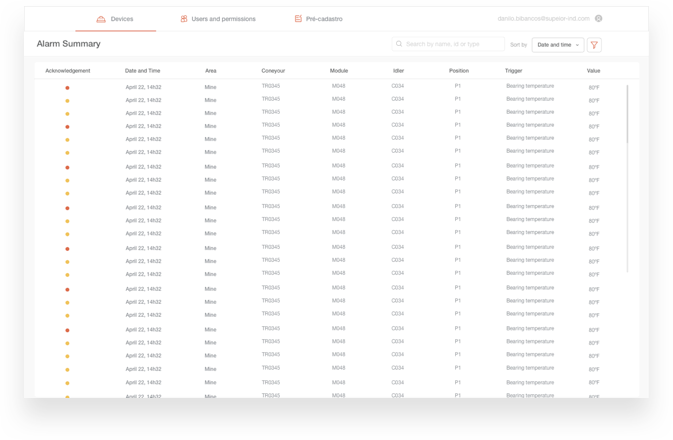

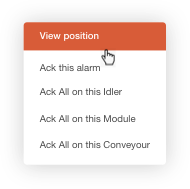

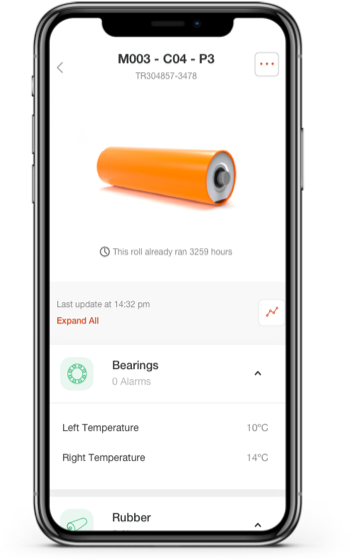

Vantage® Conveyor Monitoring measures temperatures, load, and rotation of every roll. Combined with Vantage Cloud Services our intelligent idlers allow belt conveyors to be operated and maintained as critical assets in the plant.

Scroll