Aggredry® Dewatering Washer

Low Moisture, High Profits

The Aggredry Washer is a combination wet screw and dewatering screen and can be used anywhere a fine screw might be used. The added benefits of dewatering and fines recovery pay back your investment much faster than a traditional screw.

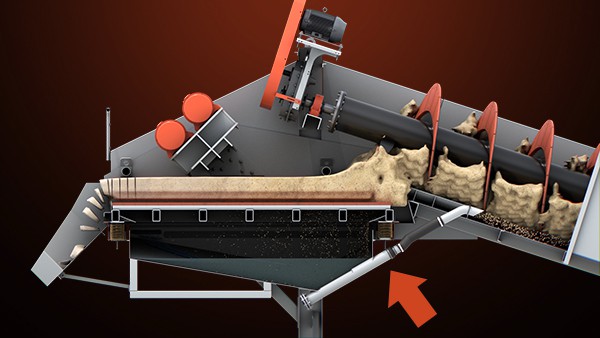

While material moves through an Aggredry Washer’s screw section, clays, dirts and fines are separated before the good sand moves to an attached dewatering screen. Here, any fines lost during screening are flushed back to the screw.

This patented jet is constantly reclaiming and preventing valuable material from ending up in your waste pond.

Sand discharges from the end of the Aggredry Washer with a moisture content as low as 8% (compared to 15-25% from a traditional screw) and is instantly available to sell.

Applications:

Sand Manufacturing

Fine Recovery

Bulk Dewatering

Concrete Reclamation

Salt Reclamation

Waste Removal

No More Wasted Water

Christopher Larson is focused on sustainability initiatives, the latest being a new sand washing system that allows cost-efficient fines recovery and conserves valuable water resources at his quarry.

Are you flushing away profits?

The Aggredry Washer’s patented Fines Recovery Jet saves valuable material from being lost to your tailings pond. Use this calculator and find out the additional profit you could earn when you reclaim those fines instead.

Advantages

01.

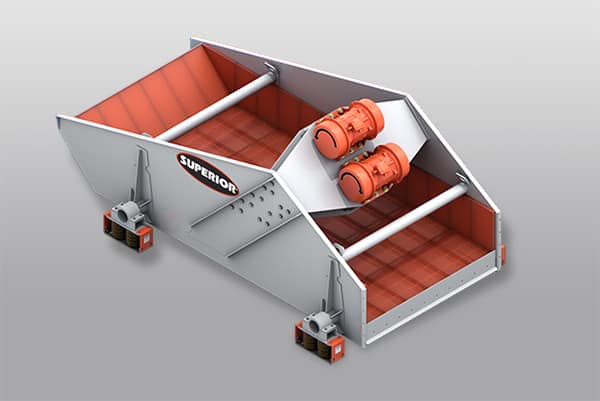

Fine Material Screw

Washes sand-sized products usually defined as 3/8” (76mm) and less. Unwanted silts are separated and removed during the process.

02.

Dewatering Screen

A deeper bed depth that’s combined with special sidewall screen media produces a drier product from this all-in-one screw/screen.

03.

Fines Recovery Jet

Valuable ultrafines that collect below the screen are flushed back to the screw and saved from the waste pond. (Patented)

04.

Low Moisture sand

A traditional fine screw leaves 15-25% moisture in the final product while the Aggregry Washer leaves just 8-12%.

Mobilize Your Sand Washing

One of the most popular configurations for wet plants at Superior is our Portable Aggredry Wash Plant. Material is fed to a Guardian® Wet Screen, which rinses and separates 3-4 products.

The onboard Aggredry Washer takes the sand for a more thorough wash and significant dewatering cycle. It all sets up in minutes and you’re producing instantly sellable aggregate.

Local Stock. Local Support. Local Experts!

Videos

Central Texas Stone uses a Portable Aggredry Wash Plant to produce “the cleanest sand in Texas.”

Learn how the Aggredry Washer eliminates disadvantages common to traditional sand washers.

Back to top »

Inventor and washing guru, John Bennington, details the perks of owning an Aggredry Washer.

models

Have questions? Need a quote? Complete the form below and we will follow up shortly.

GET DRIER SAND | Aggredry dewatering washer

See our privacy policy.